Genesis Magma Racing has fired up the engine of its GMR-001 LMDh car for the first time. Overseen by parent company Hyundai Motorsport’s head of powertrain, Julien Moncet, and engine workshop leader Rob Benson, the fire-up procedure went exactly as planned, the team says.

The event – described by Genesis Magma Racing team principal Cyril Abiteboul as “the first heartbeat” of the project – marked a key step in the development of the GMR-001, which will take Genesis Magma Racing into the Hypercar class of the FIA World Endurance Championship in 2026.

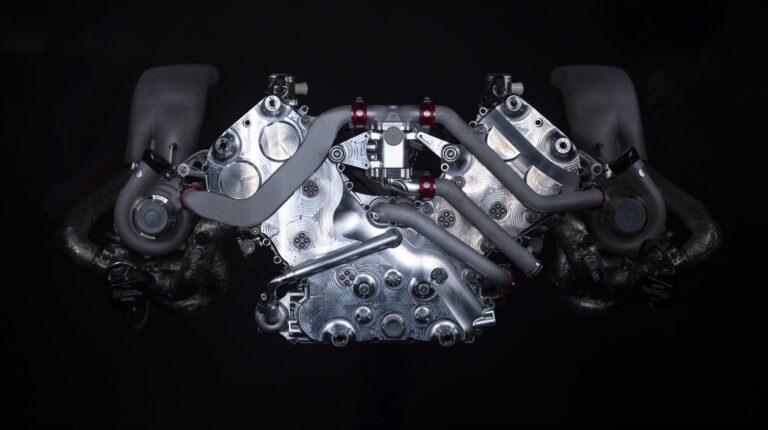

GMR-001 will use a powertrain based on an engine designed for Hyundai’s WRC car, albeit in V8 form. Hyundai has built its engines in-house since 2017, having formerly used Pipo Moteurs-supplied powertrains. Having begun as a handful of engineers in 2013, the team’s powertrain department has grown to encompass design, workshop, testing, electronics and software departments, and is capable of developing a full engine.

Abiteboul said, “Hyundai Motorsport is the backbone of Genesis Magma Racing, and the development of the engine for the GMR-001 Hypercar is the perfect demonstration of this. We have a huge wealth of expertise at Hyundai Motorsport, so to develop the powertrain for the GMR-001 it was only natural to call on the people we have.”

“We have a very strong team in Hyundai Motorsport,” explained Moncet. “We have everyone working on the powertrain all together, so the communication is very good between the departments, feeding information back between simulations. This can speed up the development process and means we can immediately adapt as soon we see something, without losing time.”

WRC roots

The basic architecture of the V8 powerplant is derived from the inline four-cylinder WRC motor, with the two units sharing roughly 60% of their parts. The I4 engine, in turn, is based on the FIA’s Global Race Engine regulations.

“The I4 engine is a very, very sophisticated, very efficient engine,” said Hyundai Motorsport technical director François-Xavier Demaison. “It’s a proper race engine, so it’s a very good base for developing an engine for WEC. Rallying is a sort of endurance race, so for the 24 Hours of Le Mans, it’s a good place to start from.

“With the time we had available to develop the engine, we immediately knew we did not have time to completely design a new engine from scratch. For the main part of an engine you need a long time to design, validate and of course to produce. Every part needs to be tested over many kilometres, and the I4 engine from our World Rally Championship car has already been well proven. It became the logical step to carry over as many parts as possible from the four-cylinder engine.”

Design work on the V8 engine began in June 2024 and was completed four months later. The assembly of the first engine was undertaken in the first months of 2025 in time for the scheduled fire-up.

Moncet said, “The first part of the project was to extrapolate what we knew from the WRC engine into endurance racing, then we focused on making improvements to aspects like efficiency and reliability, design and simulation working hand-in-hand to define the engine. The assembly of the first engine always takes a bit more time, as we pay extra attention to the details because we don’t know the engine. We had to learn and build the documentation together. It took about three or four weeks, but we completed the first fire-up exactly as scheduled.”

Further technical details of the engine and powertrain will be revealed later in the development process.

Successful fire-up launches next stage of engine testing

Hyundai Motorsport engineers, working with their Genesis Magma Racing colleagues, will now focus on completing a series of bench tests with the engine, before connecting it first to the car’s gearbox and finally the hybrid unit common to all LMDh-specification cars.

Abiteboul expanded on the future steps for the engine development: “After the first crank and the first revs in a steady state, we will progressively add more heat into the system, performing long runs. Then with different dynos we can test in a more dynamic way, more closely reproducing the cycles the engine will do around a racetrack like Le Mans. We can test equipped to the gearbox and the hybrid system until we have the full powertrain.”