Stellantis has debuted its 2.0-liter Hurricane 4 Turbo four-cylinder, with an output – 324 horsepower at 6,000 rpm and peak torque of 332 lb.-ft. from 3,000-4,500 rpm – that gives it the muscle to confidently propel a variety of vehicle sizes, ranging from compact to full size. The engine design includes flexibility for conventional, hybrid and plug-in hybrid powertrains.

“The Hurricane 4 Turbo name is appropriate because this engine packs a punch, as the variable geometry turbocharger, the high-performance combustion and the twin fuel system deliver 162hp/l of displacement,” said Micky Bly, Stellantis senior vice president and head of global propulsion systems. “The clean sheet design gives our customers a powerful, refined, smooth-running engine that uses 10% less fuel to deliver 20% more power than our current 2.0-liter DOHC I-4.”

The first application for the Hurricane 4 Turbo will be the 2026 Jeep Grand Cherokee.

Combustion technology

Central to the Hurricane 4 Turbo’s fuel-efficient power is the turbulent jet ignition (TJI) combustion technology, typically used in top-tier racing engines.

The passive TJI system in the Hurricane 4 Turbo uses a spark plug to ignite a small amount of fuel in a cup-like pre-chamber atop each cylinder. The burning fuel expands and jets into the combustion chamber, triggering a faster and more complete burn of the air-fuel charge, which enables better performance and fuel efficiency.

Stellantis engineers have combined the TJI combustion and turbocharging with a Miller Cycle operating strategy that closes the intake valves early to optimize engine efficiency and reduce emissions. This enables the Hurricane 4 Turbo to use a power-generating 12:1 compression ratio without risk of engine-damaging knock (early ignition) while using regular (87 octane) gasoline.

Each cylinder of the Hurricane 4 Turbo has two spark plugs, one for the TJI chamber and one for the combustion chamber. Ion sensing is used for misfire detection.

Efficient power and performance

The Hurricane 4 Turbo engine combines port fuel injection and high-pressure direct injection (350bar/5,076psi), with the engine controller deploying either system — or both— based on operating conditions. During cold starts, both systems activate to speed catalytic converter light-off. At idle and low loads, port injection minimizes NVH and particulate emissions. Under typical power demands, both systems operate with a variable ratio, while at peak power and maximum torque, direct injection supplies most of the fuel.

The Hurricane 4 Turbo features a variable geometry turbocharger with active vanes, producing up to 35psi (2.4 bar) of boost. It delivers strong low-rpm power and torque, providing 90% of peak torque between 2,600 and 5,600rpm. Pressurized air from the turbo passes through a liquid-to-air charge cooler, lowering intake temperatures for a denser, more powerful combustion charge. The design enables Stellantis engineers to achieve high-power density without compromising low end torque and transient performance, while keeping the overall package compact, compared with a conventional twin-scroll turbocharger.

The engine also uses an electric-powered water pump and a variable displacement oil pump to reduce parasitic losses.

Solid foundation

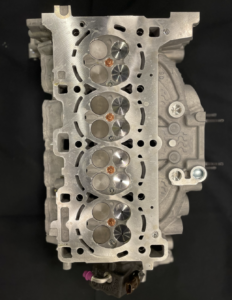

A die-cast deep skirt aluminum block, produced by Stellantis, provides a solid foundation for the Hurricane 4 Turbo.

The engine’s structural stiffness is enhanced to help minimize noise, vibration and harshness – thicker cylinder bore walls (24% thicker compared with the current 2.0-liter DOHC I-4) and larger main and connecting rod bearings on the crankshaft. A structural windage tray and balance shaft assembly is mounted low in the engine. A viscous crankshaft damper helps reduce vibrations.

The aluminum cylinder head contains four valves per cylinder and overhead camshafts. The TJI chamber is press-fit into the center of each combustion chamber for simplified assembly. Variable intake timing is adjusted quickly by an electric camshaft phaser, which delivers smoother startups. Exhaust valves are sodium-filled for heat management.

The engine also features an ultra-thin, low-friction plasma transfer wire arc (PTWA) coating in the cylinder bores. Compared with conventional iron cylinder liners, the PTWA coating has 10 times the wear resistance.

In related news, Introducing Elettrica: the first full-electric model in Ferrari’s history