Monumo has used its machine learning Anser engine to achieve an 11.4% reduction in the bill of materials (BOM) for an EV powertrain, including a 23% reduction in magnet volume. Monumo says these advances could save OEMs up to €50m (US$57m) for every million motors produced.

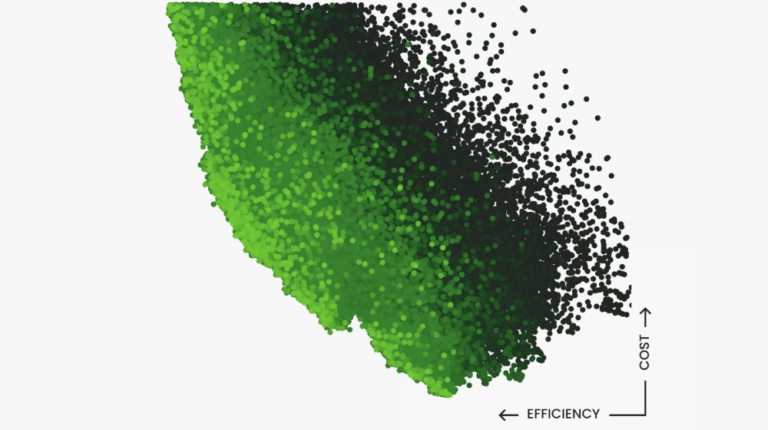

The deep-tech company coupled AI and machine learning (ML) with traditional engineering expertise to redesign the electric motor. Its Anser machine learning engine is said to be able to produce 800,000 designs in 72 hours, with industry-leading accuracy. Through these improvements in simulation, Monumo has been able to explore complex system-level interactions.

The emergence of low-cost EV competition in China means that traditional automotive powerhouses are under pressure to reduce the production cost of an EV powertrain as a key priority. In March, a McKinsey report recommended that accelerating product development cycles and reducing product costs were both integral to the European automotive industry regaining competitiveness.

Through its collaboration with Hofer Powertrain – aimed at shortening powertrain development timelines – and recent cost-related advances, Monumo has shown that the Anser engine can offer reductions in both development time and cost.

With battery prices forecast to drop significantly (Goldman Sachs predicts nearly 50% by 2026) and charging speeds improving, the electric motor remains the critical frontier for cost reduction if EVs are to truly compete on price with internal combustion engine vehicles.

Dominic Vergine, CEO and co-founder of Monumo, said, “From working with a number of global OEMs and Tier 1s, it’s clear that the pressure to remove cost from electric motors has never been more acute. Permanent magnets account for 30-50% of the total cost of an EV motor. Monumo can, today, reduce the use of permanent magnets by almost a quarter with a total cost per unit reduction of over 11% – all while maintaining the same motor efficiency.

“Our Anser engine is already reaching new heights that surpass human ability, but these results are just the beginning. If European manufacturers adopt AI, along with the continued reduction in battery costs and reduced charging times, the price point can become competitive with ICE vehicles. Even more importantly, it offers Europe a better chance at competing with the Chinese EVs currently flooding the market.”