Nissan has adopted valve seats manufactured using cold spray technology, marking a world-first application in automotive engines. The cold spray technology is being applied by Nissan to its latest 1.5l turbocharged engine, which is exclusively designed for power generation within the third-generation e-Power hybrid powertrain.

The first vehicle to feature the e-Power system, the Qashqai compact crossover, began production at Nissan’s factory in Sunderland, UK, in July.

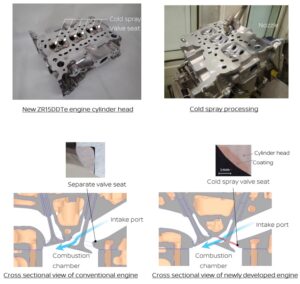

Valve seat design for new engine

The engine employs Nissan’s proprietary STARC 2 concept, which is able to elevate thermal efficiency to 42% by stabilizing in-cylinder combustion.

A key element of the STARC concept is minimizing airflow turbulence from the intake port into the combustion chamber, thereby generating a strong tumble flow.

In conventional engines, the design of the intake port is constrained by the necessity for press-fitted, sintered valve seats, which limit the ability to optimize port shape for ideal tumble flow. Nissan engineers addressed this challenge by developing a novel valve seat using cold spray technology. This process allows a coating to be directly formed onto the cylinder head surface, eliminating the need for a separate valve seat component and enabling an optimized intake port geometry. Furthermore, compared to similar methods, its higher thermal conductivity enables improved cooling performance around the valves.

The alternative valve seat is produced by spraying dissimilar metal powders at supersonic speed onto the aluminum alloy cylinder head surface, forming a robust and durable coating that adheres strongly without melting the base material.

Cold spray technology

Cold spray technology operates below the melting points of the materials involved, enabling the bonding of dissimilar metals without melting. This process prevents the formation of excessive intermetallic compounds and microvoids (porosity) that are common in traditional fusion welding methods. As a result, cold spray coatings exhibit superior adhesion, durability and reliability.

The process incorporates a specially developed cobalt-free, copper-based alloy with excellent thermal conductivity, in-house nozzles inspired by polishing techniques used in forged mold production, and AI-driven quality assurance systems.

Updates to the e-Power hybrid powertrain

e-Power is Nissan’s electric-drive powertrain, which combines a compact gasoline engine, battery and electric motor. The engine functions solely as a generator, providing electricity to power the motor – delivering a fully electric driving experience without the need for external charging.

In addition to the advanced 1.5-liter turbocharged engine, the latest e-Power adopts a 5-in-1 modular electric powertrain unit which integrates the electric motor, generator, inverter, reducer and increaser into a compact and lighter package. This unit delivers significant improvements in both fuel efficiency and cabin quietness.

In related news, Ford recently announced that it is investing approximately US$5bn across its Louisville Assembly Plant and the BlueOval Battery Park in Michigan to deliver a new pickup and produce advanced prismatic LFP batteries, and has launched its new Ford Universal EV platform and Ford Universal EV Production System