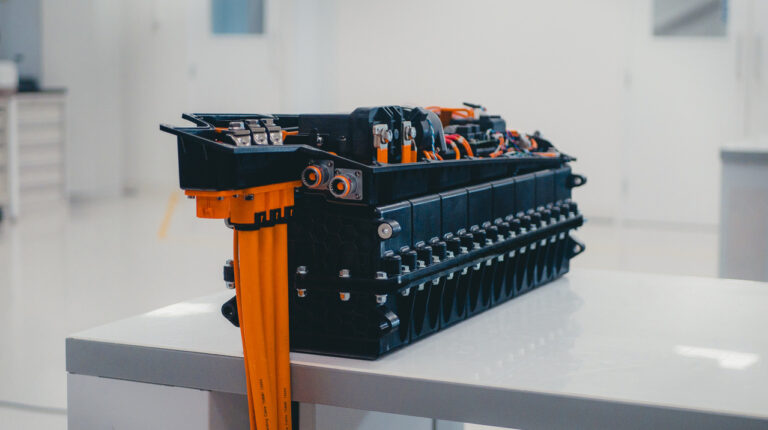

RML Group has been awarded Conformity of Production (CoP) certification for its battery systems.

Following a rigorous audit by UCA, an independent body appointed by the certifying authorities, RML’s quality management systems have been confirmed to consistently produce products in line with UN ECE Regulation 100, the key safety standard for electrified powertrain components.

“This is an important step forward for RML,” said James Arkell, head of powertrain, RML Group. “It really highlights the in-depth technical capability and quality standards RML adhere to. Performance is a key part of what RML offers – doing this safely, reliably and repeatably is key to our success, and this certification solidifies that message to the industry.”

CoP certification is widely regarded as a minimum requirement for suppliers working with major automotive manufacturers. It signifies that not only can a company design to strict safety standards, it can also build to them reliably and at scale. With this approval, RML moves firmly into the realm of Tier 1-capable suppliers.

The certification is part of RML’s broader push to homologate its VarEVolt battery platform and positions the company to bid on larger scale contracts that go well beyond prototyping or ultra-low volume production.

“This certification puts clear water between us and a number of smaller start-ups in the EV space. It underlines our readiness to move from prototyping and niche volumes to supporting larger production contracts,” Arkell added.

In related news, Göpel Electronic has developed the Caroline series of acoustic testing systems to support quality assurance through noise and vibration analysis during production. Read the full story