In the factory of the future, innovative production methods will bring major advantages that principally benefit customers. Taking a look at this future reveals the opportunities offered by additive manufacturing and new laser technology.

Christian Thönes, chairman of the executive board of tool manufacturer DMG Mori, believes that 3D printing exemplifies the physical reach of digitization: “Additive manufacturing materializes engineers’ ideas, and makes it possible to produce well-thought-through designs from the digital world in the real one.” Complex components produced using additive manufacturing need no longer consist of 80 individual parts, and could instead be created as a single, continuous piece.

And shape need no longer be a limiting factor. Structures borrowed from nature could guide the way to more effective designs for coolers encasing battery packs or fuel cells, resulting in components that take up much less space once installed, but are nonetheless twice as effective as traditionally produced components.

This opportunity is new because geometry and physics set clear restrictions on what can be achieved with conventional machining. A hollow shaft with interior ribbing simply cannot be produced using turning alone; and even when turning is used in combination with milling, the possibilities can be limited.

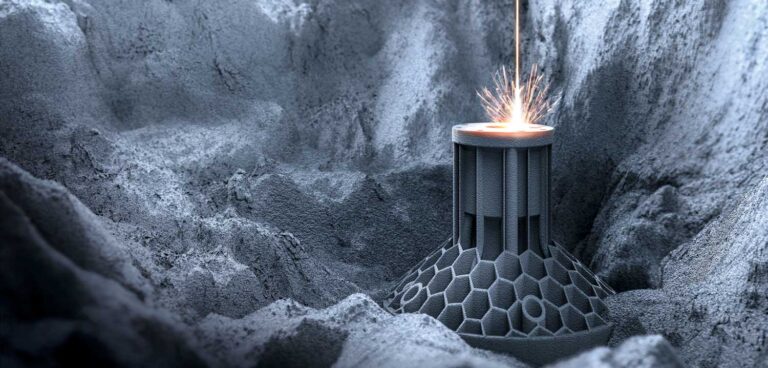

So successfully creating such components requires the combination of several individual parts. Additive manufacturing methods can produce new, durable and similarly complex components, from metal or plastic powder, using laser energy. In the Weissach Development Centre, Porsche engineers are researching these procedures in relation to components, including rotor shafts for electric engines.

There are currently two methods.

In the powder and nozzle procedure, metal powder is directed to a nozzle via a gas flow. The nozzle and a laser beam focus on the same point, where the metal powder is fused by the laser – the production head, consisting of a nozzle and a laser, can be maneuvered along up to five axes during this process.

The powder bed procedure uses a laser to fuse metal powder, which has been applied over the entire surface, at specific points; this causes the component to grow in height in several layers that are each between 20-100 micrometers thick. This method enables the production of almost any shape.

Tools produced using additive manufacturing have the advantage of improved long-term durability that arises from precisely calculated and implemented requirements, as well as being presorted for recycling at the end of their lifetime.

Thönes explains, “On the one hand, the possibilities are almost endless. We can achieve significantly lower weight, optimum function design, and absolutely customized components. On the other hand, productivity is still one of the great challenges.”

Traditional pressing, milling and casting procedures currently still have the edge in terms of speed of production. Porsche engineers in Weissach have reached the same conclusion: “It can still take up to 13 hours to print one rotor shaft like this,” says Frank Ickinger, engine pre-development, Porsche.

With an improved process in mind, engineers are now researching how to accelerate additive workpiece manufacturing, while developers are also looking to optimize the interaction between traditionally produced parts and those created using these innovative methods. The new technology could also make it easier to combine different materials. “A laser beam that creates a few thousand degrees Celsius in a focused manner can be used to fuse stainless steel with plastic,” explains Thönes.

From managers’ perspectives, the close dovetailing of innovative production techniques with advanced information technology is an element of the factory of the future – Industry 4.0. Industry 4.0 refers to production being controlled by computers to an extent far beyond actuating milling machines or industrial robots: the ultimate vision sees all machines and stations in a production process being networked with one another.

“While additive manufacturing offers many advantages, it is also clear that traditional production processes – such as turning and milling – will continue to have their place in future,” notes Thönes. Traditional, highly precise machine tools continue to allow accuracies to within 0.1mm.