Texas-based Infinitum Electric has developed a new electric motor design which replaces the traditional laminated stator with one that uses PCBs. Currently, the company is supplying motors into industrial settings, for applications such as HVAC. Now, it is looking to branch out into the automotive sector, following an agreement with a Tier 1 supplier to develop a motor for hybrid applications based on its IEm Series. ETI spoke to company founder and CEO Ben Schuler to find out more about the company’s novel approach to motor design.

Can you provide an overview of the motor technology?

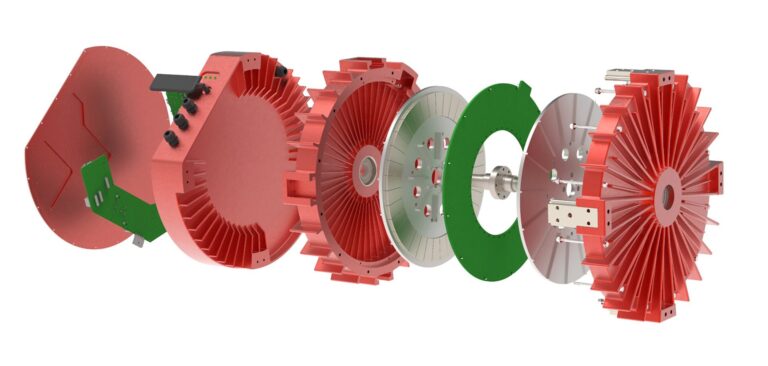

It is a permanent magnet, synchronous motor in an axial configuration. Rather than a traditional stator, we used a PCB. Basically, the printed circuit board stator pulls out all of the iron laminations and copper windings and instead, we etch copper conductors into a printed circuit board. That effectively removes all of the core losses out of the stator and it makes for a drastically higher efficiency motor that’s smaller, lighter, more durable [than traditional designs]; all the good things that folks are interested in. Another interesting attribute is that removing the iron eliminates the cogging and the torque ripple and that makes for a drastically quieter motor.

Does the design bring with it manufacturing challenges or advantages?

As the motor is lighter, it inherently uses less natural resources to produce than a conventional motor of a similar output. It can be produced anywhere; there are thousands of PCB manufacturing firms all over the world and you don’t have to have specialist equipment to make the motors. The lack of tractive force between the rotor and stator also makes it very safe and easy to assemble.

Because we do not need to have special dies created to stamp laminations etc, we can be very flexible with the stator design, and create variations without a lot of effort. For example, if a customer wants a smaller diameter, longer length motor, we can do that. If they want a larger diameter, and shorter length, we can hit that as well. In terms of cost, we are drastically more cost-effective solution than traditional architectures.

What is the scope for power density with the motor design?

The motors have the potential for up to a 250kW output and a power density of 12kW/kg. Currently, the motors we have produced only rely on air cooling over the stator, but we are also looking at using oil cooling techniques to increase the power density.

Does the motor have the capability to feature integrated power electronics?

In other industries, like HVAC, we have the power electronics integrated; whether we go that way with the auto industry is to be determined, and will be application-specific depending on what packaging demands our customers have.

Are there durability advantages to the PCB stator design?

Are there durability advantages to the PCB stator design?

I would say that the PCB stator, by pulling out all of the core losses, allows us to operate at high RPM and maintain efficiency at those RPM. In a traditional motor the core losses are constant, with ours, the higher the RPM the more of an efficiency advantage we have. Also, the elimination of the iron core, by limiting the cogging and torque ripple, reduces vibration. Additionally, all of the coils in the stator are equally insulated so the coefficient of thermal expansion is also equal. That means as they are cycled on/off, the thermal performance of the stator is very good and better than any iron laminated stator. The combination of those factors really improves the durability of the motor.

Does the PCB approach open up the possibility of easier sensor integration to the motors?

We do add sensors, in our IEs Series of general-purpose motors for fans, pumps and compressors. With those we incorporate the IOT sensors directly into the stators and VFD. They are constantly monitoring variables such as power, speed, vibration, temperature and pressure. We also have a cellular module which allows us to easily connect to the cloud, and that can be used to download firmware updates.