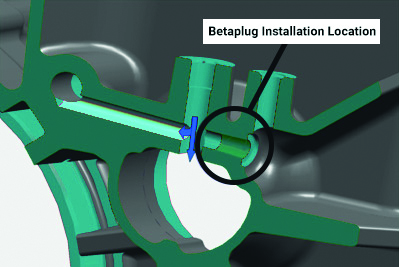

An automatic transmission case is a very complex casting incorporating a sophisticated valve body with multiple cross-channels and passages. Often it is necessary to drill through the casting to create these channels, creating cross-drillings. Doing so leaves a hole in the shell, which must be sealed to prevent fluid loss.

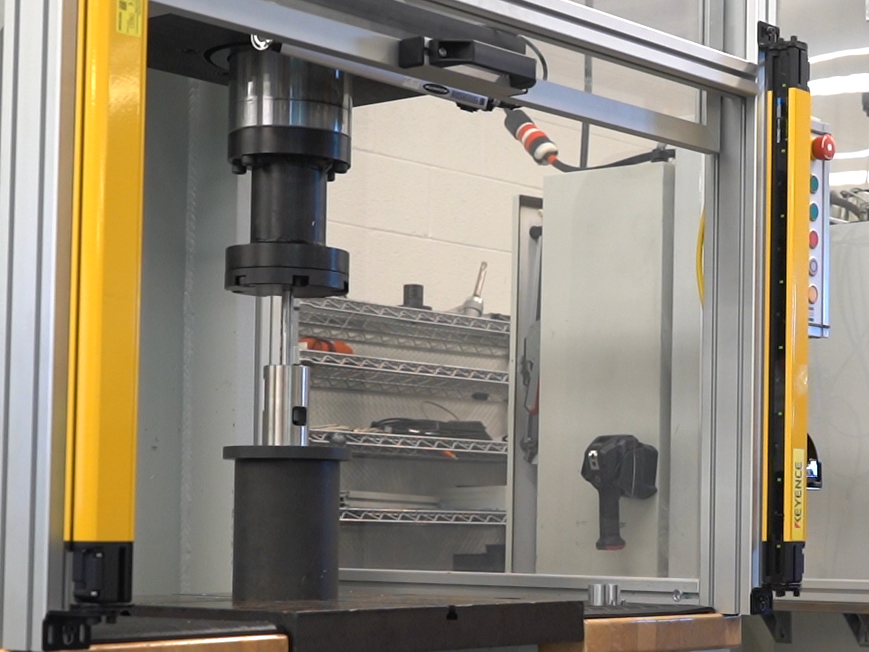

A long-time Promess customer uses an electromechanical assembly press (EMAP) to press a steel ball bearing into these holes to seal them. This sealing method worked in previous applications, but on a particular thin-walled transmission case it led to cracking of the housing, unacceptable leakage rates and warranty issues.

The EMAP is an electric servo press instrumented to monitor and precisely control peak force and final position. In this case the user programmed the ball-pressing application to stop at a specific distance, and only the distance was controlled. Neither the dimensions of the ball nor the diameter and surface finish of the hole were held to tight tolerances. As a result, the same level of force could leave the ball in a wide range of positions, which caused leakage and cracking of the thin-walled case.

Faced with unacceptable cracked housings and yield issues, the manufacturer decided to replace the steel ball with a Betaplug expansion plug from The Lee Company. This pre-assembled, two-piece tapered expansion plug has an inner pin and an outer plug body with lands and grooves that bite into the housing during

the installation process.

The Betaplug product is installed in a matching tapered bore that creates a perfect fit, reducing unnecessary expansion and giving a predictable stress level, ideal for brittle materials or thin wall conditions. The installation tool is designed to install the inner pin below flush while staking over the back edge of the plug body.

Assessing the situation

Use of the Betaplug expansion plug eliminated the cracked housing and production yield issues. However, the manufacturer carried over an improper installation specification that created new manufacturing problems – an unacceptable scrap rate, yield issues and damages in the fixturing. The manufacturer contacted Promess, supplier of the EMAP, and The Lee Company. Both companies were asked to examine the complete installation and assembly process and suggest a solution to the high scrap rate.

The Lee Company engineers determined that the Betaplug products were being over-pressed, which produced excessive radial force when the pin moved to expand the plug body and extruded the plug into the installation bore. The manufacturer was reluctant to change the distance-based programming because plugs that were installed successfully were not failing in the field. They were not happy with the scrap rate, but they were willing to accept it.

A proper installation for a Betaplug product should be terminated when the staking is complete, regardless of where the unit is within the bore. The manufacturer’s engineers wanted to install the plug at a fixed point within the bore – where the steel ball plug had performed best – regardless of the optimum staking location. However, in a tight bore this generated the excessive installation force that extruded the Betaplug expansion plug.

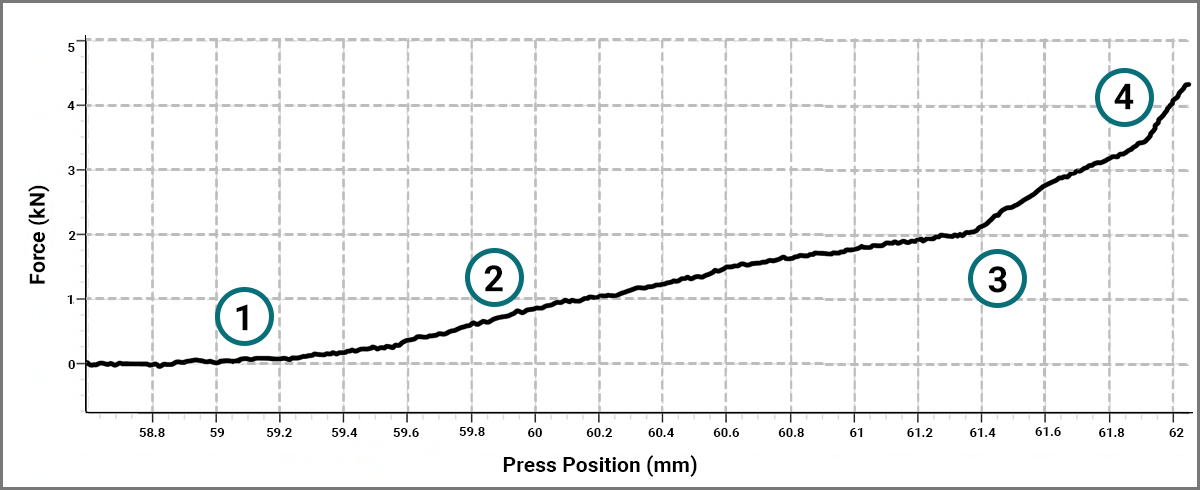

Promess engineers recommended that the manufacturer alter its process to measure more than a simple force level or distance. The engineers highlighted the benefit of combining EMAP instrumentation with the sophisticated data processing capabilities of the Promess Motion Controller. This gives the ability

to measure and control absolute force and distance, as well as more complex relationships such as the rate of change between those measurements.

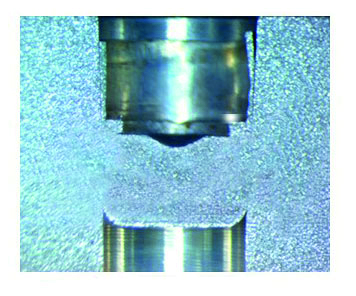

During installation the Betaplug product initially moves as a unit until the lands on the outer plug body begin to dig into the bore. When adequate resistance is achieved, the plug body stops moving but the inner pin continues to move and generates the expansion force that creates leak-tight seals and ensures retention. When the pin is 0.5-0.8mm below flush, the installation tool stakes over the top edge of the plug body.

This transition produces a readily detectable inflection point in the rate of change relationship between press force and distance, making it a simple matter to stop the press when the pin is appropriately inserted into the plug body. The programming can also detect parts that are upside down, sideways, or missing a pin or other component.

Promess engineers and their Lee counterparts performed extensive laboratory testing to validate the new programming. This was done prior to installing the upgraded application in the manufacturer’s plant, where further trials were performed.

Plug and program solve the problem

The new EMAP program and the corrected installation procedure solved the installation yield issues and reduced the scrap rate. It was in fact determined that many of the scrapped parts – previously discarded because the Betaplug products were not inserted to the originally specified distance – were perfectly acceptable and would not have failed in the field. Since the change to the plug and program, over 35 million plugs have been installed and used in the field without any warranty returns for leakage.