The use of aluminum metal composites could help improve the weight and efficiency of traction motors, according to UK-based specialist Alvant. The company has created a process known as Advanced Liquid Pressure Forming (ALPF), a method by which it brings together aluminum, which acts as the matrix, and a high-strength reinforcement fiber to create a high-performance AMC material.

Compared with unreinforced metals, AMCs can have higher strength, greater stiffness, lower weight, superior wear resistance, lower coefficients of thermal expansion and superior electrical conductivity. Alvant added that AMCs can be twice as strong as engineering steels for the same weight, as well as up to 50% stiffer.

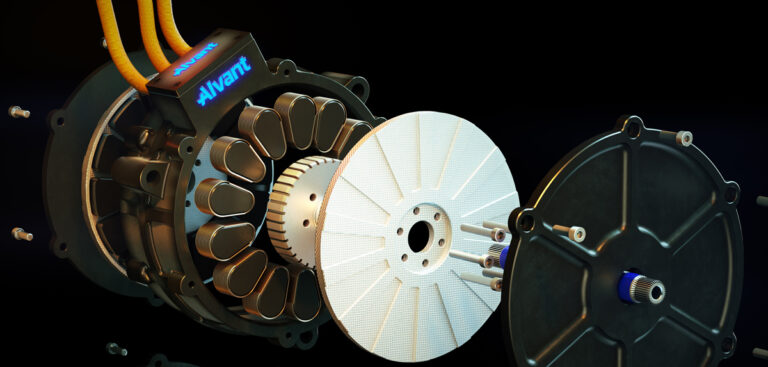

This scope to significantly increase component strength and stiffness while reducing weight has been now been used to improve the efficiency and responsiveness of electric rotors used in electric and hybrid vehicle traction motors. In conjunction with UK motor manufacturer Yasa, which specializes in axial flux motors (AFM), engineers at Alvant have developed a rotor that is 40% lighter than the original, steel rotor version.

Alvant said the new rotor also increases the power potential of the motor compared with one manufactured using traditional materials, as the increase in stiffness afforded by the AMC construction allows for closer tolerances and thus a reduction in the air gap between the rotor and stator.

Additionally, the improvement in strength and stiffness means rotor speeds can be increased (AFM units tend to run slower than comparable radial flux motors, due to their greater diameter) which, in turn, increases power density by a claimed 225-300%. When combined with the reduced rotating weight, this means overall mass and inertia are also reduced.

Looking specifically at the rotors used in axial flux motors (AFMs) suitable for passenger cars, if these were made from AMCs, rather than steel, mass and inertia would be reduced by 45-73%, and overall motor weight by 19kg to 25kg on one of Yasa’s automotive offerings.

The company said the exact weight saving depends on which of the three most common types of AFM is used: in AFMs with electrical steel cores, the weight saving would be 45% per motor; in AFMs with soft magnetic cores, the saving is 50% ; and in AFMs with a Halbach Array the saving is 73%.