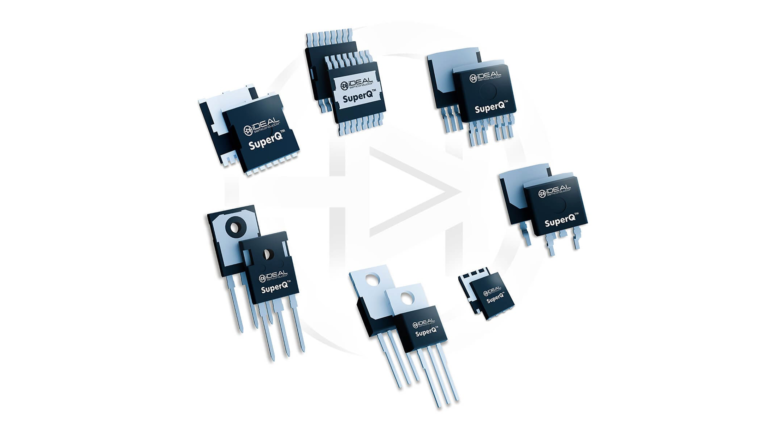

Ideal Semiconductor has launched its SuperQ MOSFET technology, purpose-built to solve the critical safety and efficiency trade-off in high-voltage (72V and higher) battery management systems (BMS).

The growing adoption of high-voltage battery packs in e-mobility presents a challenge: managing the risk of failure during external short-circuit events, where currents can reach thousands of amps. The discharge MOSFET – metal-oxide-semiconductor field-effect transistor – is the component responsible for safely isolating the battery pack under such conditions.

“In high-energy packs, robustness is non-negotiable,” said Dr Phil Rutter, VP of design at Ideal Semiconductor. “Traditional MOSFET designs are forced to compromise between achieving ultra-low RDS(on) for efficiency and the structural integrity needed to survive a massive short-circuit current. The SuperQ platform eliminates this compromise. Our proprietary cell structure delivers the market’s lowest on-resistance alongside a safety margin that is simply unmatched, giving designers the confidence to build smaller, more reliable and lower-cost battery systems.”

The SuperQ solution features a proprietary cell structure with a wider conduction region that maximizes power density and structural integrity under extreme stress. Following internal testing, the SuperQ’s iS15M2R5S1T (150V, 2.5mΩ, TOLL package) went head-to-head against a leading competitor. The test revealed the SuperQ device exhibited 1.4 times higher short-circuit failure capability than its closest competitor.

In related news, Infineon and Munich Electrification partner to advance high-voltage battery management systems