Rimac Technology has unveiled its latest portfolio of advanced battery and powertrain technologies, including next-generation solid-state solutions and evolutions of its current batteries and e-axles.

Batteries

Working in collaboration with ProLogium and Mitsubishi Chemical Group, Rimac has developed an advanced battery system featuring solid-state cell technology and innovative housing solutions. ProLogium’s solid-state cells are integrated with Mitsubishi Chemical Group’s advanced materials expertise to create a battery platform that is lighter, safer and more energy dense.

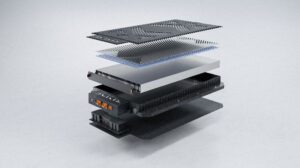

Based on 46XX Gen2 NMC cells and next-generation thermoplastic composite battery housing (Pentatonic) co-developed with Kautex Textron, Rimac’s Evo Technology is an alternative platform that combines cell chemistry with packaging and thermal management solutions.

Branching into hybrid solutions, Rimac has designed a hybrid platform to address two key market demands: high-energy hybrid battery packs based on the 46XX cell format and power-dense hybrid packs based on the 2170 cell format. It offers scalability and interchangeable cell configurations, integrated in cell-to-pack architecture with advanced safety and thermal management features.

Powertrains

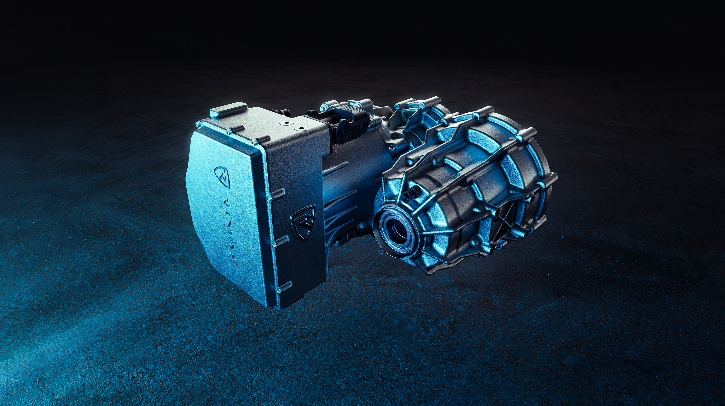

The SINTEG 300 and 550, single EM ultra-compact, fully integrated e-axles offer performance with power density exceeding 8kW/kg and torque density surpassing 90Nm/kg. The powertrain features a patented ultra-light rotor able to spin up to 25,000rpm and a novel magnet design. Based on Rimac’s scalable powertrain platform, the CoAxial or Offset configurable variants offer 150-360kW and 2,500- 6,250Nm to target performance-focused vehicles across all segments, from hot hatches and sports coupes to sedans and SUVs.

Rimac has also announced that the High Torque XXL Axle version of the Dual EM EDU 550 e-axle will enter series production in 2026 for a global OEM. The current validated system has proven >95% peak efficiency and delivers over 11,000Nm of axle torque.

Electronics and controls

Rimac Technology has also added to its portfolio of domain and zonal ECUs, powered by NXP’s S32E2 real-time processors. By consolidating multiple traditional ECUs into single high-performance domain controllers, Rimac offers a centralized architecture. These next-generation ECUs manage critical functions ranging from torque vectoring and high-voltage battery systems to body and power distribution controls, while assisting software-defined vehicle (SDV) adoption and over-the-air (OTA) updates.

These technologies were unveiled at IAA Mobility and will be produced at Rimac’s facilities in Croatia. “What we’re showcasing at IAA represents the convergence of breakthrough innovation and production readiness,” said Nurdin Pitarević, COO of Rimac Technology. “These aren’t simply concept technologies; they’ve been developed to be production-ready solutions that will power hundreds of thousands of vehicles in the coming years.”

In related news, UK’s Faraday Institution has pledged £9m for advanced battery research and commercial scale-up