Globally, battery demand grew by 70% in 2023 compared with 2022, driven by rising electric vehicle (EV) sales. Safety has remained a top priority, as the high energy density of lithium-ion batteries poses a risk of failure if operating conditions stray from their design parameters. As EV battery use has increased, effective battery management systems (BMS) have become critical to prevent thermal runaway and other adverse outcomes. MathWorks senior product marketing manager Danielle Chu discusses the process of developing a BMS using modeling and simulation.

China’s Ministry of Industry and Information Technology has announced that mandatory safety standards for electric vehicle (EV) batteries will come into effect on July 1, 2026. The new regulation is the world’s first standard that requires batteries to prevent fire and explosion, even after internal thermal runaway occurs. Safety is a critical concern in EVs. The high energy density of lithium-ion batteries, a typical choice in EVs, poses risks of failure if the operating conditions deviate from those for which the battery has been designed. A battery management system (BMS) is critical in preventing negative outcomes, including thermal runaway – an uncontrollable exothermal reaction leading to the destruction of the battery.

The primary functions of a BMS include monitoring current, voltage and temperature to prevent overcharge and over-discharge; balancing the charge across the cells; estimating the battery’s state of charge (SOC) and state of health (SOH); and controlling the temperature of the battery pack. These functions are critical, as they affect the performance, safety, battery lifetime and user experience of the electric vehicle. For example, by preventing overcharge and discharge beyond voltage limits, the BMS prevents premature aging of the battery, ensuring that the vehicle remains performant over its operational life.

The advantages of using simulation in BMS development

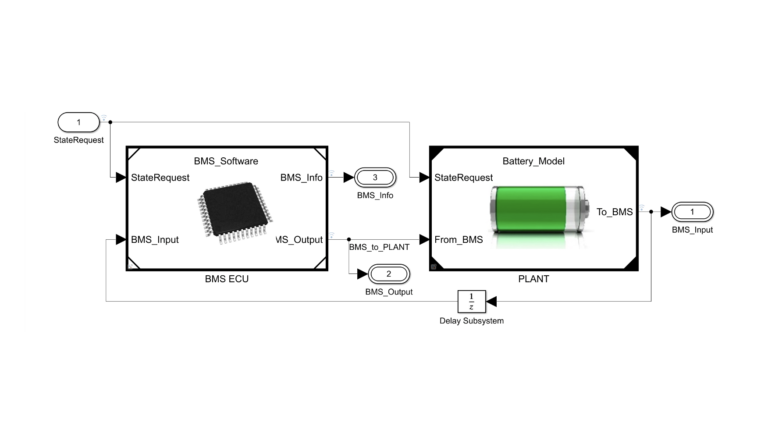

Engineers simulate the battery plant model, environment and BMS algorithms on a desktop computer using behavioral models. They use desktop simulation to explore new design ideas and test multiple system architectures before committing to a hardware prototype. Desktop simulation enables engineers to verify functional aspects of the BMS design. For example, they can explore different balancing configurations to evaluate suitability and trade-offs between them. Simulation is also instrumental in requirement testing; for example, engineers can verify correct contactor behavior in the presence of an isolation fault. Evaluating the system’s behavior during a fault is another clear example of the use of simulation to replace hardware testing.

Once the design is validated using desktop simulation, engineers can automatically generate C or HDL code for rapid prototyping (RP) or hardware-in-the-loop (HIL) testing to validate the BMS algorithms running as code in real time. With RP, code is generated from the BMS algorithms model and deployed to a real-time computer that performs the functions of the production microcontroller. With automatic code generation, algorithm changes made in the model can be tested on real-time hardware in hours rather than days. In the case of HIL testing, code is generated from the battery plant models rather than the BMS algorithm models, providing a virtual real-time environment that represents the battery pack, active and passive circuit elements, loads, charger and other system components. This virtual environment enables engineers to validate the functionality of the BMS controller in real time before developing a hardware prototype.

Simulation enables engineers to dramatically reduce the time from design to code generation, allowing for rapid modeling of various techniques with enhanced speed and efficiency. Altigreen Propulsion Labs engineers used a simulation-based approach to model and iteratively test different techniques for SOC estimation, such as Kalman filtering and Coulomb counting, and designed a comprehensive one for their SOC estimation. Prathamesh Patki, principal engineer and control systems head at Altigreen, says, “Embedded Coder has cut development time in half. Whatever we conceptualize, we can get it running in the shortest amount of time on the real hardware.”

BMS development use cases

Cell characterization is the process of fitting a battery model to experimental data. Accurate cell characterization is essential because the BMS algorithm uses the battery model to set control parameters such as those of a Kalman filter for SOC estimation or power limits based on SOC and temperature to avoid undervoltage or overvoltage conditions. Later in the BMS development cycle, engineers can use the same battery model for system-level closed-loop desktop and real-time system simulations. Tools such as Simscape Battery provide multiple approaches to battery modeling, including equivalent circuit, electrochemical and reduced order modeling using neural networks.

Charging speed is a key performance indicator in EV design and adoption. The high power levels of fast charging stress the battery materials and reduce its lifetime. Therefore, it is essential to optimize the power profile during fast charging to ensure maximum charging rate and minimal stress on the battery. This is achieved with a combination of simulation and optimization. The charging time is minimized while stress factors are kept within acceptable ranges.

Production code generation complements BMS design workflows compliant with formal certification standards in the automotive industry. For example, when LG Chem (now LG Energy Solution) developed the BMS for the Volvo XC90 plug-in hybrid, Autosar was a requirement standard. LG Chem chose to model and simulate the BMS algorithms and behaviors as an integral part of their design workflow. The number of software issues identified in each software release dropped from about 22 to fewer than nine – well below the target for the project. The BMS LG Chem developed for Volvo using Autosar has achieved ISO 26262 functional safety-based certification for Automotive Safety Integrity Level C (ASIL C).

Conclusion

Using modeling and simulation in BMS design accelerates development, lowers costs and leads to safer, more efficient electric vehicles. By thoroughly testing BMS algorithms across a wide range of operating and fault scenarios, engineers can be more confident that the software will perform reliably in real-world conditions, minimizing the need for expensive physical testing. This approach ultimately helps ensure the final product not only meets but also surpasses industry standards and customer expectations.