Kistler has launched the 4012A absolute pressure sensor for hydrogen pressure measurements, designed to deliver reliable measurements to optimize hydrogen-fueled combustion engines and for pressure monitoring in fuel cells. The sensor has demonstrated high hydrogen resilience through testing.

The growth of a large-scale hydrogen economy poses challenges for measurement technology. Hydrogen diffusion and accumulation can cause material embrittlement, while infiltration into sensor elements may distort measurement accuracy.

Combustion engines operated with hydrogen or alternative H2-based fuels are almost emission-free, paving the way for decarbonized mobility – with engine developers using hydrogen-resistant sensors to optimize hydrogen combustion – and Kistler’s hydrogen pressure sensor has been designed to support this mobility transition. The sensor can be used for gas exchange analysis as well as pressure measurement in the low-pressure fuel supply rail of hydrogen engines.

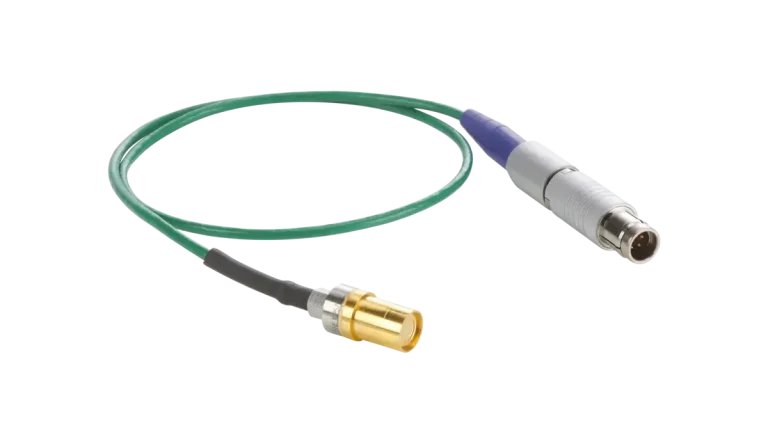

The 4012A sensor enables hydrogen pressure monitoring in the low-pressure range of fuel cells, with piezoresistive absolute pressure sensing available in two ranges: up to 20 bar and 50 bar.

In related news, Comemso electronics has launched SmartCal, a solution for calibrating and adjusting its in-house battery cell simulator (BCS)