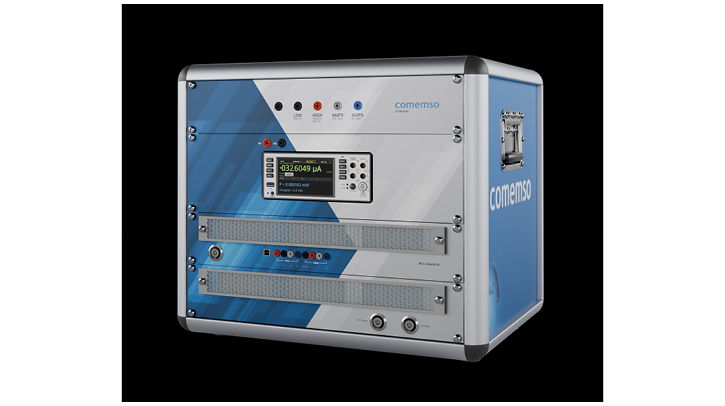

Comemso electronics has launched SmartCal, a solution for calibrating and adjusting its in-house battery cell simulator (BCS). The system has been designed for developers and testers of battery management systems (BMS) to enable fully automated calibration of the Comemso BCS, at the customer’s premises or in the Comemso laboratory.

Accuracy

SmartCal combines intuitive user guidance with an automated calibration process. It uses a 6.5-digit digital multimeter that is calibrated in accordance with ISO 17025. For in-house calibration, the system stores all measurement and calibration data centrally in the Comemso database for maximum traceability. For calibrations performed by the customer, the data is stored locally in the device and automatically output as a PDF calibration report.

Flexible use

In addition to verification, SmartCal also offers the option of adjusting individual channels to ensure maximum measurement accuracy in the long term. The system can be purchased or rented and can be flexibly integrated into laboratory and production environments.

“If you want to develop good BMS, you have to be able to test them precisely. With SmartCal, we ensure that our customers can maintain the high measurement quality of their BCS over many years – simply, automatically and precisely,” explained Dr Kiriakos Athanasas, CEO of Comemso.

Automotive, research and energy storage systems

Comemso’s SmartCal was designed for developers in the fields of electromobility, battery management and high-voltage test environments, as well as those responsible for their BMS end-of-line (EOL) test systems. The option of decentralized calibration on site eliminates time-consuming and costly returns and downtimes.

In related news, Göpel Electronic has developed a powerful and quickly configurable battery test bench