Hyundai has detailed development its Road Noise Active Noise Control (RANC) system. Based on the company’s current Active Noise Control (ANC) technology, the new system aims to dramatically reduce in-cabin noise.

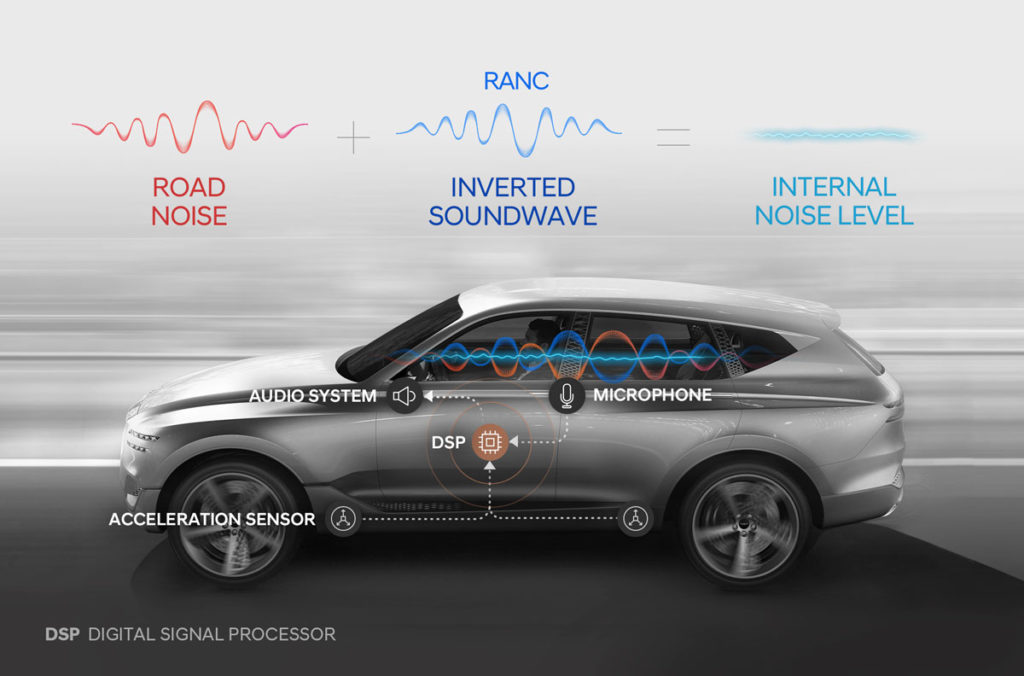

The company’s ANC technology actively reduces noise by emitting soundwaves inverted to incoming noise. It is a software-driven solution that analyses the in-cabin sound to decrease engine and road noise.

With RANC, Hyundai is able to analyze various types of noise in real-time and produce inverted soundwaves. Using an acceleration sensor, RANC calculates the vibration from the road to the car and the control computer analyzes road noise.

As its computation and signal transfer speeds are optimized, it takes 0.002 seconds to analyze the noise and produce an inverted soundwave, generated by a Digital Signal Processor (DPS).

The microphone constantly monitors the road noise cancelation status and sends the information to the DSP. RANC is able to conduct accurate noise analysis and rapid computation to combat road noise for the driver, passenger and rear seats separately.

Based on tests evaluating road surface, vehicle speed and different seating positions, RANC was able to reduce in-cabin noise by 3dB. The technology will begin to be applied to an upcoming Genesis model.

“RANC is a remarkable technology which takes existing NVH technology to the next level,” said Gangdeok Lee, research fellow at Hyundai’s NVH research lab, “We will continue to take the leading position of NVH technology and deliver the highest level of quietness to customers.”