As Audi makes final preparations to tackle the Dakar Rally next month, it has laid out details of the RS Q e-tron’s cooling system, which handles both electric and IC powertrain components as well as keeping driver and co-driver in (relative) comfort.

“Audi has never contested the Dakar Rally before. The first question we asked ourselves was: How do we get the heat out of the car?,” said Sebastian Fröber, the engineer responsible for the cooling systems, summarizing the central question regarding cooling. “We started with CFD simulations for the aerodynamics of the overall vehicle. Then we designed the individual cooling systems.”

Audi’s experience with complex cooling requirements, such as in the three-time Le Mans-winning R18 hybrid, as well as with its Formula E program, apparently stood it in good stead for the challenge of Dakar. However, the objectives with Dakar are clearly different: whereas maximum aerodynamic efficiency was the priority in the Le Mans sports car, the desert prototype is about the best possible heat dissipation. Achieving this requires the use of multiple cooling circuits.

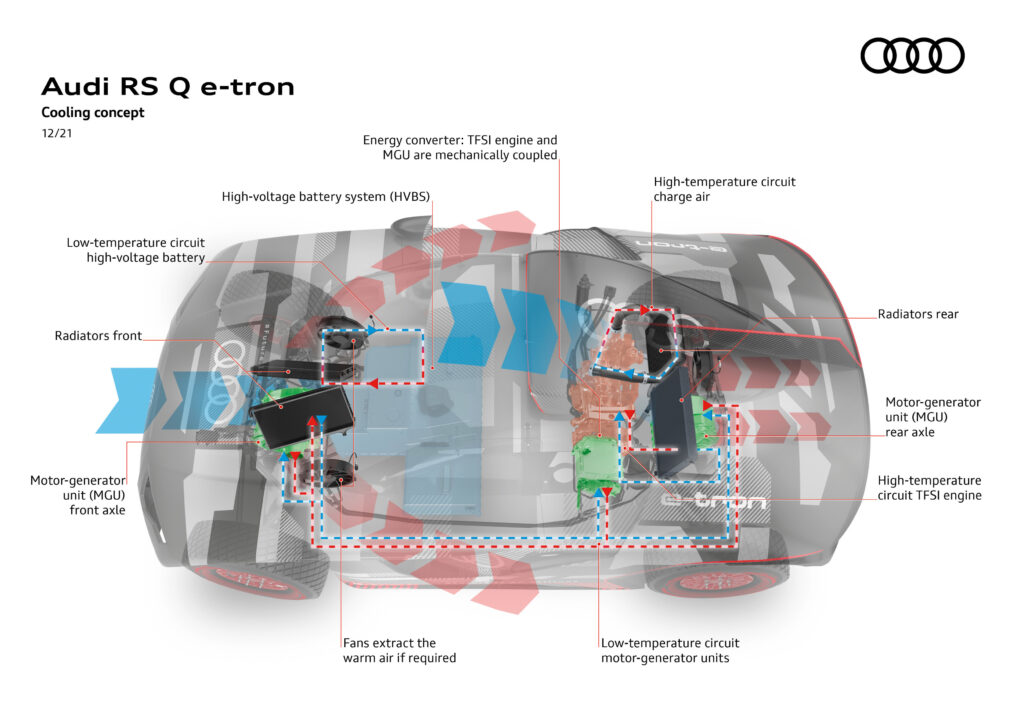

Starting with the heart of the electric drive, its high-voltage battery system, Audi uses a liquid cooling system with a dielectric coolant called Novec, with the low-temperature circuit utilizing a radiator under the front hood.

Meanwhile, the car’s three MGUs (motor generator units) are connected via their own low-temperature cooling circuit, which dissipates heat via the left radiator in the front end of the vehicle. Audi noes that this low-temperature circuits posed a particular challenge for its engineer due to the high temperatures experienced on the Dakar and low temperature delta between the ambient air and coolant.

“This is because 40° desert air only marginally cools 60° coolant because of the small temperature difference,” said Fröber. With the electric machines having to run at considerably lower temperatures than the IC engine, the cooling system must therefore be highly efficient to protect the motors.

An oil cooling loop is also located in the left front air duct in front of the low-temperature radiator. This circulates the hydraulic oil for the power steering, which is subjected to high loads during off-road driving. The system also supplies the two jacks on the right and left side of the vehicle via valves in case a puncture forces the crew to change the wheel. In the right front air duct there is also the condenser of the air conditioning system. Another fan in the car circulates the air in the cabin.

Finally, the IC engine, which is positioned transversely behind the passenger seat, has its own fluid circuit with a radiator. An engine oil circuit is thermally connected to this system via an oil-water heat exchanger. There is also a charge cooling circuit for the inlet charge which relies on a heat exchanger above the rear axle, next to the oil cooler. A cowl on the roof divides the air flow between the two radiators.

“In difficult passages, for example when crossing dunes at slow speeds, this air flow may not be sufficient,” stated Fröber. “For this reason, a fan sits behind each of the two radiators, which can extract the warm air if necessary.” It exits at the rear of the Audi RS Q e-tron.

“We last secured the thermals in Morocco in November,” noted Fröber. “Carlos Sainz traversed the soft sand of a dried-up riverbed with deliberately taped cooling air intakes in a lengthy test. All systems worked flawlessly.”