UK-based startup electric vehicle (EV) battery business Ionetic has launched its latest EV battery pack design platform. The new platform is said to cut development costs and time-to-market for vehicle manufacturers with new models.

It is expensive and time-consuming for automotive companies to produce safe and high performing battery packs which also offer fully customized designs. However, off-the-shelf battery pack systems can have issues with low energy density and poor optimization.

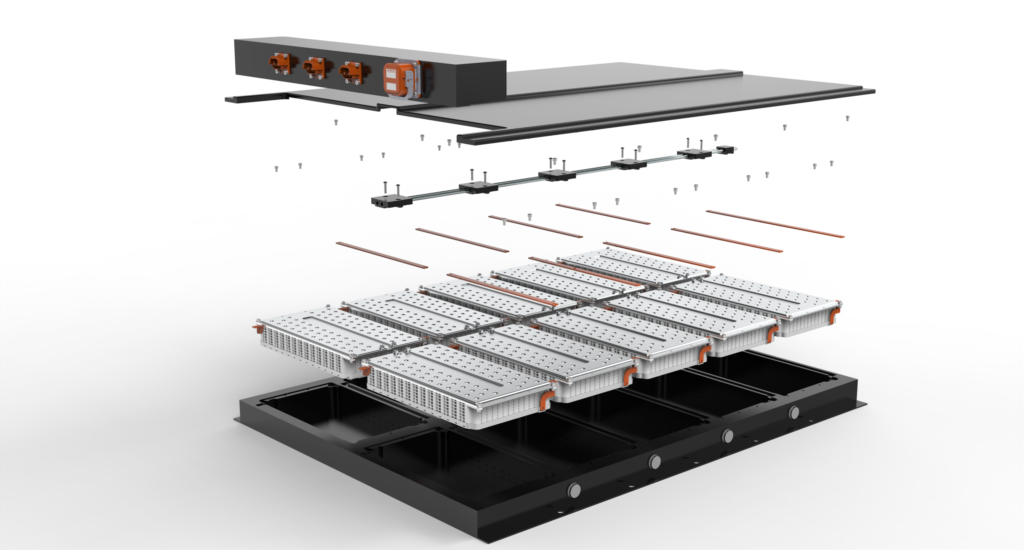

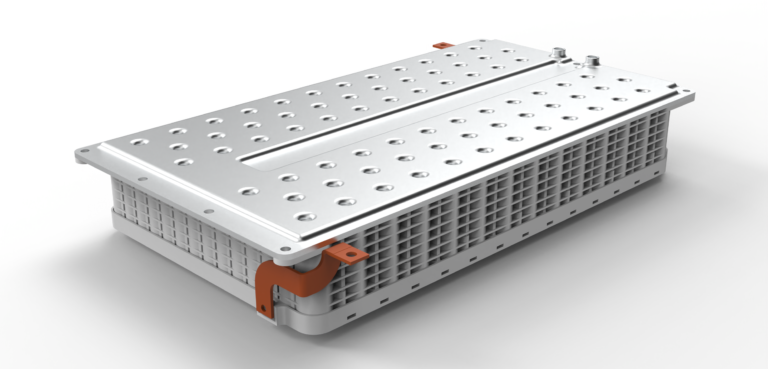

Ionetic’s latest battery solution, however, delivers a combination of cost and customization to accelerate battery pack development. The company’s software-based platform can boost energy density by 30% and increase utilization of pack volume by up to 120%, compared to alternative off-the-shelf solutions.

Battery pack designs can be created in a matter of days, reducing the cost of progressing from requirements to mass manufacture for a claimed 90% of OEMs. This is possible because the Ionetic platform can automatically generate designs according to a series of fully adjustable parameters. It can also offer a vertically integrated solution to battery pack production, which includes homologation and mass manufacturing.

With plans to open its first UK-based battery manufacturing facility in 2023, Ionetic will be able to begin pilot production of its own battery pack designs. This would position the company as the only battery pack developer in the country capable of offering complete end-to-end, in-house battery solutions.

“There are many stages needed to get a battery pack into production,” said James Eaton, CEO and co-founder of Ionetic. “Automotive companies need to consider requirements, system design, homologation, embedded control, manufacturing options and vehicle integration, to name a few. These stages are often done by different companies, which can lead to a costly, fragmented process. At Ionetic we facilitate all these stages, simplifying the process and reducing the cost for EV OEMs.

Eaton continued, “We’re currently focusing on niche automotive companies in the UK and Europe. They typically make less than 10,000 vehicles per year, so probably don’t meet the minimum order quantities of large global battery pack suppliers or can’t meet their high design fees. These niche vehicle makers are the unsung heroes that keep society functioning. Trucks, buses, construction vehicles, service vehicles and emergency vehicles all need to electrify in the next decade. We’re also in talks with iconic car brands and sports car manufacturers. Gigafactories are mainly catering for mass-produced, cars. There’s a risk that some of these niche, historic car brands might not survive electrification unless companies such as Ionetic address their specific needs.”

“The EV battery sector is set to grow 15-30% annually for the next 10 years and so there is a huge opportunity for an agile startup such as Ionetic,” said Dr Monica Marinescu, co-founder of Ionetic and senior lecturer at the department of mechanical engineering, Imperial College London. “At a time when competition in this space is stronger than ever, it is crucial automotive companies pursue battery technologies that provide a balance between performance, cost reduction and resource optimization.