With the increasing electrification of vehicles worldwide, the demand for highly efficient, compact and reliable power systems continues to grow – not only in passenger cars but also in electric two-wheelers. Electric two-wheelers require special systems, such as HV-LV DC-DC converters for xEVs (electric vehicles and their variations) and traction inverters for electric two-wheelers. Infineon Technologies has expanded its OptiMOS 6 portfolio with the Automotive 150 V MOSFET family, designed to meet the demanding requirements of modern electric vehicles (EVs).

The automotive MOSFET family offers two drain-source resistance levels across all device variants. All variants are rated for the 150V voltage class and deliver the lowest RDS(on) available in this class, reaching as low as 2.5mΩ. This enables minimal conduction losses and high efficiency. The tight distribution of the gate threshold voltage (VGS(th)) supports synchronization when multiple MOSFETs are used in parallel configurations, which is particularly relevant for high-power automotive systems. The devices also feature low switching losses up to high frequencies, allowing for highly efficient operation in fast-switching applications such as modern DC-DC converters. In terms of thermal performance, the variants achieve a thermal resistance as low as 0.4K/W. This significantly improves heat dissipation, reduces system-level cooling requirements and lowers associated expenses.

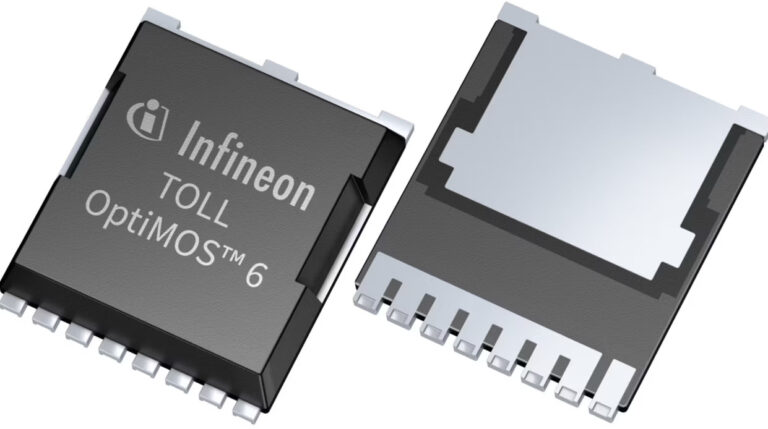

The devices are available in three package types that offer specific advantages. The TO-Leadless (TOLL) 10 x 12mm² enables a compact design. The 10 x 12mm² TOLG package is footprint-compatible with TOLL, with the additional feature of gullwing leads for high robustness against thermal-mechanical stress. Meanwhile, the 10 x 15mm² TOLT package features a top-side cooling concept that enables efficient heat dissipation on the system level, making it well-suited for thermally demanding applications in space-constrained environments.

Infineon’s OptiMOS 6 150 V MOSFETs are qualified by Infineon Automotive Quality and exceed the requirements of the AEC-Q101 standard. In addition, they are PPAP capable.

In related news, Mahle has begun producing e-compressors at its Morristown, Tennessee, location. Nearly 50 new employees will be manufacturing e-compressors for the North American market