ZF has unveiled a next-generation electric range extender system that it says will go into production at the start of 2026. The electric Range Extender (eRE) and the electric Range Extender plus (eRE+) have been designed to meet dynamic market and customer requirements as well as flexible drive concepts.

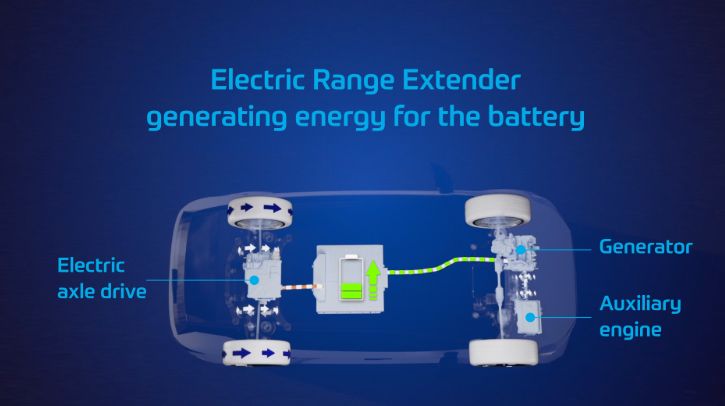

A range extender is a combustion-powered engine coupled to an electric motor that generates power for the vehicle battery when its state of charge drops below a certain threshold. Both the eRE and the eRE+ variants are said to be highly integrated designs that are flexible in terms of performance, E/E architecture, 400V or 800V and semiconductor type.

The eRE connects an electric motor with an integrated inverter, suitable software and planetary gearset. The eRE+ also features an intelligent clutch and a differential. As a result, it can be used either as a current generator or as an additional secondary drive, which aims to save manufacturers from developing a separate component. Performance can be scaled for both models. The output ranges from 70kW to 110kW (eRE) or 70kW to 150kW (eRE+).

ZF notes that range extenders are more relevant in regions where a charging infrastructure is not yet reliable. “Although the all-electric range of passenger cars is around 500km on average, range anxiety still influences a wide range of buyers when choosing their next vehicle,” explained Dr Otmar Scharrer, senior vice president R&D, electrified powertrain technology, ZF. “These [the next generation of range extenders] represent a real alternative to larger – and thus more expensive – batteries or plug-in hybrids.”

ZF says that a further advantage of a range extender over plug-in hybrid electric vehicle (PHEVs) or conventional combustion engines is that the unit operates in the ideal performance range for fuel consumption and lower CO2 emissions. Compared to parallel-hybrid drive solutions, for example a PHEV, range extenders are said to be compelling due to their lower additional costs, shorter development cycles, reduced platform integration effort and simplified supply chain management. This makes the technology particularly interesting for manufacturers who are new to the market and may have little experience with traditional combustion engine drivelines.

“The new interest and the increased demand for range extenders shows that the potential of this technology is far from exhausted, in particular for model platforms that are already designed for battery-electric drivelines,” said Scharrer. “Behind our solutions is a system and platform concept. This means that we are optimally equipped to be able to respond to all customer and market requirements with shorter development cycles.”

In related news, Hyundai Motor Group’s next-generation hybrid powertrain system has recently been unveiled. The system features a new transmission with two integrated motors that can be paired flexibly with internal combustion engines across the Hyundai line-up, delivering a system output from the low-100ps range to the mid-300ps region, allowing for a broad application from subcompact to large vehicles. Click here to read the full story.