LEM has launched a new current sensing unit for battery management in electric vehicles (EVs). For the first time on the market, LEM has put together shunt and open-loop Hall effect technologies in a single part, called a Hybrid Supervising Unit (HSU), to meet the challenges of small footprint, low cost and highest safety level in EV battery management systems.

“The HSU represents a significant innovation in sensor technology, being the first to combine shunt and Hall effect sensing into a single component. This integration simplifies system architecture, enhances safety and allows for seamless upgrades without altering the mechanical layout. Additionally, it reduces the total bill of materials (BOM) and minimizes cycle time at the customer’s end,” said Jérémie Piro, product manager of battery management systems and battery storage at LEM.

The EV’s high-voltage BMS plays three key roles: managing the battery’s state of charge and state of health, keeping the system and end user safe and performing cell balancing as part of the battery optimization process. For higher safety levels, system engineers typically use two separate devices: a shunt to measure 2,000A and a current sensor fully isolated for measurements to 2,000A.

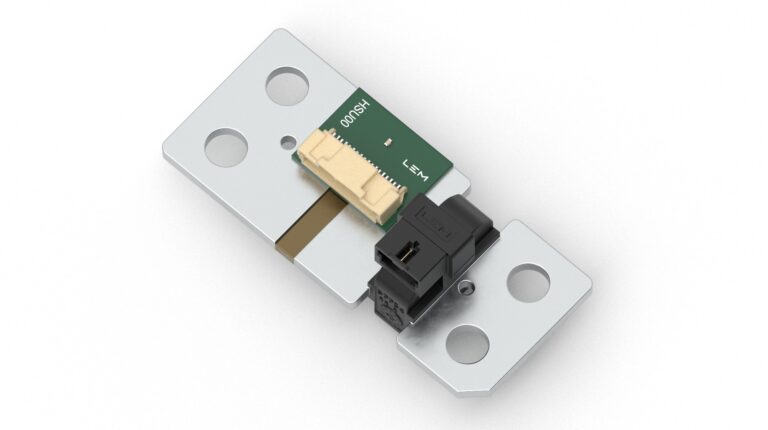

LEM has combined the capabilities and performance of both technologies into a single unit, integrating it into the BDU. The signals from each section – the shunt and the current sensor – are then collected by the BMS.

At the BDU level, the HSU offers a minimal footprint, weight and cost (BOM) while minimizing the effort to accelerate time-to-market. It also allows for easy system upgrade – without affecting the mechanical layout – while improving safety. At the BMS level, the HSU supports system developers in achieving the ASIL D safety standard required for EVs.

The shunt’s resistance is very low at 25µΩ, and the Hall part is galvanically isolated, with accuracy of 2% at 500A and 5% at 2,000A. Signal communication lines are separated (shunt signal and analog or digital bus for the Hall part), and there is NTC (negative temperature compensation) signal for shunt temperature compensation.

The current measuring range is up to ±2,000A at 10s for both parts, with a wide operating temperature range of -40°C to +125°C.

LEM says the HSU is the only component on the market with two technologies fitted into a standard shunt footprint. It is a plug-and-play unit, allowing easy mounting. LEM is initially offering the HSU00 part, with HSU01 to follow soon. Both are suitable for the two most common BDU busbar sizes: 84 x 36 x 3mm (HSU00) and 84 x 20 x 3mm (HSU01).

In related news, RML Group has been awarded Conformity of Production (CoP) certification for its battery systems