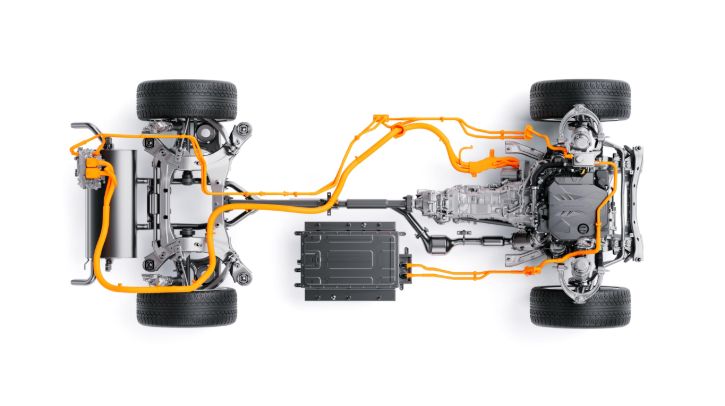

Hyundai Motor Group’s next-generation hybrid powertrain system has been unveiled. The system features a new transmission with two integrated motors that can be paired flexibly with internal combustion engines across the Hyundai line-up, delivering a system output from the low-100ps range to the mid-300ps region, allowing for a broad application from subcompact to large vehicles.

The transmission includes a new P1 motor that handles starting, battery energy generation and energy deployment to assist propulsion. The transmission’s P2 driving motor is responsible for propulsion and regenerative braking. Various additional electrification-focused technologies have been incorporated in the hybrid system.

“We have developed an innovative new hybrid system that integrates our long-accumulated engine, transmission and hybrid system development experience with the electrification technology applied to our world-class electric vehicles,” said Dong Hee Han, executive vice president and head of Electrified Propulsion Test Center, Hyundai Motor Group. “We will continue to develop innovative technologies that actively utilize electrification capabilities during the transition to EVs, providing customers with eco-friendly vehicles that offer superior performance.”

Improved engine design

The first powertrain with the next-generation hybrid system uses a newly developed gasoline 2.5-liter turbo hybrid unit, enhancing the design and control technology of the existing 2.5 turbo gasoline engine. A new, next-generation gasoline 1.6-liter turbo hybrid powertrain will also be available.

The 2.5 turbo hybrid system utilizes an ‘over-expansion cycle’, intentionally delaying intake valve closure during compression to lower the effective compression ratio of the mixed gas in the cylinder while maintaining a high expansion ratio during the combustion process. An improved piston design and an expanded triple fuel injection range aim to enhance combustion speed, stabilize combustion and suppress detonation.

Transmission and engine

Connecting the P1 motor directly to the engine reduces engine start time. Precise control of engine load and the driving force of the P1 and P2 motors enables the engine to operate within a high-efficiency range, improving fuel efficiency.

The gasoline 2.5 turbo hybrid system used in the all-new Hyundai Palisade boasts a maximum fuel efficiency of 14.1km/l, a maximum system output of 334ps and a maximum torque of 460Nm, offering approximately 45% greater fuel efficiency, 19% more maximum power and a 9% improvement in maximum torque compared with a 2.5 turbo gasoline model.

The next-generation gasoline 1.6 turbo hybrid claims an improvement in fuel efficiency of more than 4% in a mid-size SUV compared with previous models, increasing the system’s maximum rated torque output from 367Nm to 380Nm and improving acceleration response.

The incorporation of the P1 motor into the active shift control hybrid transmission allows the system to achieve faster and smoother shifting performance. The P1 motor is also utilized to reduce engine vibration and booming during battery charging situations while idle, enhancing interior refinement.

Electrification technologies

Alongside the next-generation hybrid powertrain, Hyundai plans to integrate advanced electrification technologies with a line-up of electrification-focused technologies, comprising electric all-wheel drive, electrification-vehicle motion control, e-handling 2.0, electrification-evasive handling assist, e-ride 2.0, stay mode, V2L and smart regenerative braking.

The new hybrid transmission will be combined with various engines from 100-300ps, introducing a diverse line-up of hybrid vehicles from compact to large and luxury classes.

In related news, Upfit UTV, a Fox Factory subsidiary and developer of purpose-built custom vehicles, and OMI, an electric powertrain engineering company, have unveiled an off-road hybrid powertrain, dubbed OMI Fusion-Drive. Click here to read the full story.