XD Thermal Technology has advanced its side-cooling solutions for cylindrical cell-to-pack battery packs, with large-scale production capacity and automotive-grade process control positioning the company as a key supplier, the company says.

Super-fast-charging cylindrical packs contend with heat accumulation during high current/voltage in charging and discharging with high C-rate. XD Thermal’s side liquid-cooling concept routes serpentine tubes along the cell sidewall, increasing effective contact area versus bottom cooling plates. The enlarged vertical contact surface well resolved the challenge of heat gradients in Z-axial direction and eventually enables each individual cell to stay in a much more balanced temperature range, which is considered as a positive factor to maintain a longer life for Li-ion batteries.

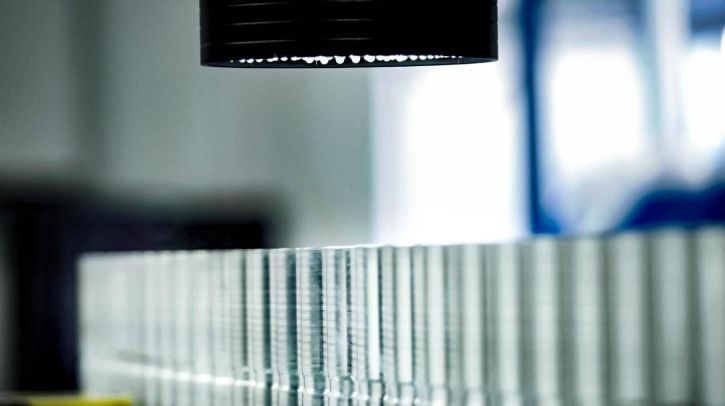

XD Thermal has developed a family platform of side-cooled modules and packs built around robust structures and reliable quality assurance methods. Cooling tubes are pitched to match cylindrical cell layouts and can be combined flexibly with different manifolds, brackets and pipelines, while validated flow-path structures and internal design rules keep heat-transfer performance predictable from prototype to mass production.

“Platformized design reduces development cost and time and supports agile development for our customers,” said Guo, a technical engineer at XD Thermal. “With proven solutions of pipeline connections, electrical insulation and geometric combinations, we helped many customers complete side-cooled battery development smoothly.”

“Ramp-up and industrialization matters as much important as product development,” said Sun, head of manufacturing engineering at XD Thermal. In 2024, the company commissioned high-volume serpentine-tube lines with a daily capacity of 30,000 pieces, integrating automated forming, welding, cleaning and 100% leak testing.

“We provide a repeatable, scalable production system with confirmed development roadmap and SOP schedule, giving us proven capability for production ramp-up and line expansion. Normally, production line and toolings preparation could be finished 6-8 weeks before PPAP,” added Sun.

In related news, GAC begins local EV production at Magna’s European plant