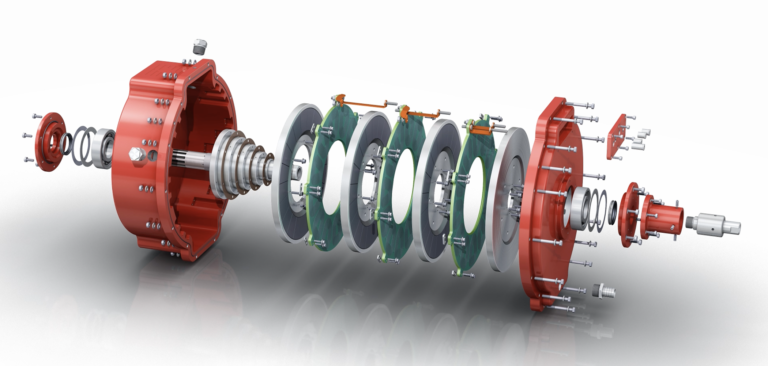

USA-based electric motor developer Infinitum has announced the launch of the Aircore Mobility axial flux propulsion and traction motor. The company’s USP is that it has replaced the heavy copper-wound iron stator found in traditional motors with a lightweight, printed circuit board (PCB) stator that is claimed to be 10 times more reliable.

The company claims that, compared with conventional motors, its motors are 10% more efficient and 50% smaller and lighter, and use 66% less copper. By replacing the iron core with a PCB stator, mechanical losses are reduced, efficiency is increased, and noise and vibration are significantly reduced.

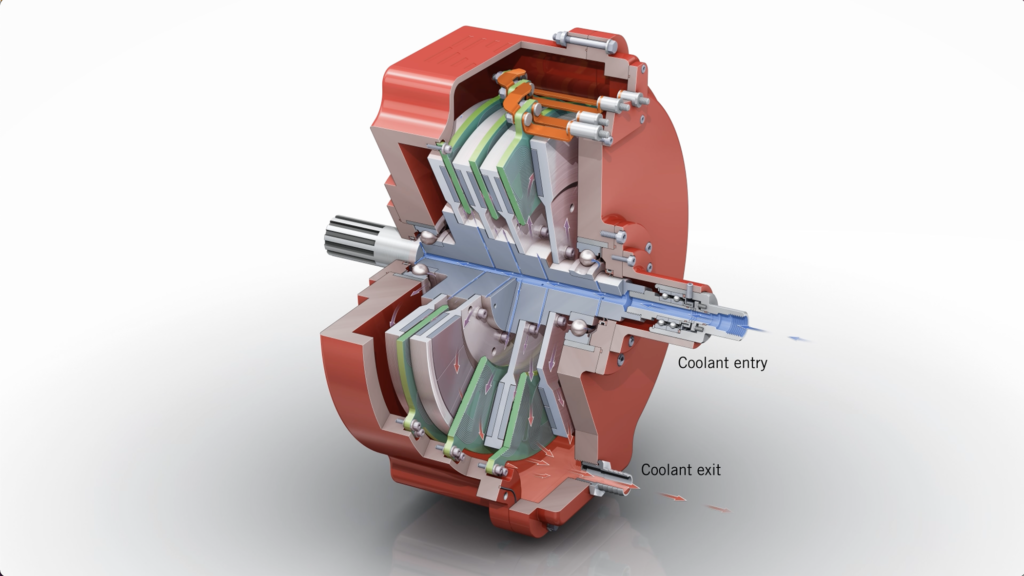

Leveraging this PCB stator design, the Aircore Mobility motor is claimed to achieve four to five times the current density of a conventional, liquid-cooled motor using a liquid cooling technique that allows the coolant to be in direct contact with the stator, mitigating heat across a larger surface area and enabling high overload capability and extended life.

“Our Aircore motor topology eliminates core losses and delivers a broader range of speeds and load conditions where the motor can operate at high efficiency levels,” said Paulo Guedes-Pinto, vice president of technology at Infinitum. “The Aircore Mobility motor offers a new avenue in extending range for Class 1-8 vehicles, aerospace, marine, construction and agricultural machines.”