BASF has launched the Ultramid Advanced N3U42G6 polyamide 9T with non-halogenated flame-retardant, adding to its polyphthalamide (PPA) portfolio. The PPA is said to minimize electro-corrosion of metal contacts in electric and electronics (E&E) parts for e-mobility.

The PPA is intended to increase the safety and durability of high-voltage (HV) connectors in inverters, DC-DC converters and batteries of electric cars, for example. BASF states that the Ultramid Advanced N grade improves the “robustness and reliability” of thin-walled high-voltage (HV) connectors, thanks to its high strength, stiffness across a wide temperature range, chemical resistance and dimensional stability. These properties assist in meeting the growing industry demand for halide-free electrical and electronic components that perform reliably in warm, humid environments.

High-voltage application

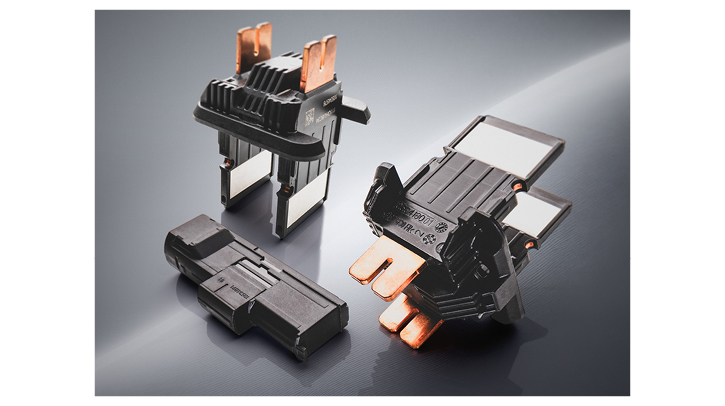

Automotive supplier KOSTAL Kontakt Systeme, an E&E specialist, uses the new Ultramid Advanced N in several components in its high-voltage connector KS22 Class 4 for high-current modules.

The high-voltage (HV) connector — the smallest in its performance class — uses BASF’s PPA material to support miniaturization and save installation space. Its excellent flowability at thin wall thicknesses makes it ideal for compact, high-performance designs. Ultramid Advanced N3U42G6 provides the connector with very high electrical insulation, which beats aliphatic polyamides, especially at elevated temperatures. It also has a high elongation at break, so there is no stress whitening when the different components are mounted.

Characteristics

The flame-retardant Ultramid Advanced N3U42G6 extends the lifetime of E&E components as it is halide-free according to EN 50642. It thus prevents contact corrosion and subsequent failure of sensitive electrical parts exposed to heat and moisture. The PPA achieves fire protection class UL94 with V-0 at 0.25mm. It also enables long-lasting color coding which is safety-relevant in areas with high voltages and meets all the criteria of color stability and heat aging resistance. In in-house tests, the color stability was confirmed after 1,000 hours at up to 150°C. For self-coloring, more than 50 inorganic and organic colorants, which are approved for coloring PPAs and show a heat stability up to 350°C, can be used.

Due to its low moisture uptake and high heat distortion temperature of 265°C, Ultramid Advanced N3U42G6 is suited for connectors post-processed with surface mount technology (SMT). BASF says it guarantees a high dimensional stability and avoids blistering or changes in dimensions of the processed part during the SMT process. The PPA grade is especially suited for SMT as it can withstand higher temperatures while maintaining its mechanical strength. This increases the quality of the post-processed E&E components and helps to reduce waste and costs.

“Our new non-halogenated grade combines the excellent properties of our superhero Ultramid Advanced N with better colorability, long color stability and outstanding anti-corrosion effect,” said Volker Zeiher, technical development engineering plastics at BASF.

“With this optimized PA9T, our customers can develop innovative, best-in-class E&E components supported by BASF’s proven flame-retardant expertise and material know-how for electronics manufacturing. Ultramid Advanced N3U42G6 is part of BASF’s tailored flame-retardant PPA portfolio for the E&E industry that advances the development of challenging parts in consumer electronics, automotive battery systems and electric powertrains.”

In related news, BASF and Group14 Technologies, a manufacturer of advanced silicon battery materials, have announced a market-ready, performance-improving silicon battery solution using commercially available materials – BASF’s Licity 2698 X F binder and Group14’s advanced silicon battery material, SCC55, providing what the companies term “a robust cycle life and transformational performance”. Read the full story here