In theJune issue of APTI, we looked at the newly developed drive units that will power VW’s Premium Platform Electric (PPE) vehicles (see Prime Cuts, June 2024, p8*). Concurrently with the development of PPE, the company also created Premium Platform Combustion (PPC), which, in the case of Audi at least, will underpin its last generation of ICE-powered passenger cars.

INTEGRATION

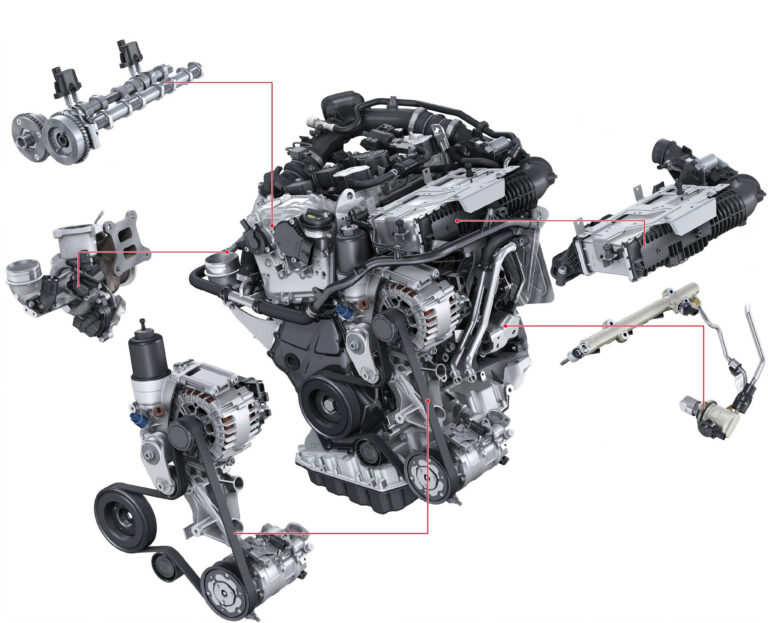

The latest generation of the EA888 has a focus on packaging ancillaries tightly around the block to aid installation in a variety of different vehicle platforms» To keep up with ever-evolving emissions regulations and customer expectations, vehicles using PPC will be equipped with a revised range of ICEs, based on the long-standing EA888 turbocharged I4, which entered series production in 2006, and the E839 turbocharged V6, which was released in 2015. The latest iteration of the EA888 will be the EA888evo5 and the new V6 will be known as the EA839evo. Both will be available with a range of mild and plug-in hybrid options.

FOUR-CYLINDER REFINEMENT

Looking to build on an already successful engine, the VW Group needed to ensure it would continue to comply with evolving emissions regulations in the US, Europe and China. An increase in output was also required while removing the need for fuel enrichment across the engine map with lambda (λ) not exceeding 1. At the same time, ease of integration to a range of VW Group platforms was a prime consideration, while being flexible enough to accommodate different hybridization options.

NEW ADDITIONS

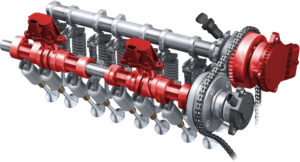

The overhaul of the EA888 is wide ranging, with new charge cooling, turbocharger, injection system and camshaft design among the changes» To improve the efficiency and output, revisions to the combustion system were required, notably an increase in compression ratio (CR) from 12.2:1 to 12.5:1 in the higher-performance versions, categorized as Performance Class 2 (PC2). For the lower-output PC1 versions, the increase was more significant, from 9.6 to 10.5:1. To counter the NVH impact of this increase in CR, an electric camshaft adjuster is used on the intake cam to reduce compression during startup. The reciprocating parts have also been reinforced, with the crankpin increased in diameter from 47.8mm to 50.0mm. The connecting rod was reduced in length from 144mm to 140mm to facilitate a thicker piston crown. A variable-geometry turbocharger (VGT) has also been employed, and the fuel injection pressure has increased from 350 bar to an impressive 500 bar. The latter required a change in drive system for the mechanical fuel pump to handle the additional loads: rather than being driven by the exhaust cam as in previous iterations of the EA888, it is now driven by the balancer shaft within the crankcase. Impressively, despite the increase in pressure, the injectors are still sealed using o-rings, though the fuel rail is a forged production to increase strength.

COMBUSTION

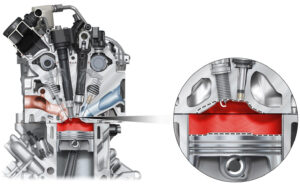

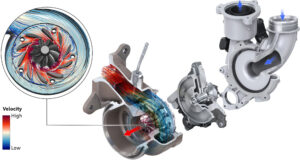

A more extreme Miller cycle is used in the EA888, necessitating a revised combustion chamber design» Coupled with the VGT is a new charge cooling system using an air-water heat exchanger, introduced to reduce packaging complexity across different model variants.

The intercooler is integrated within the inlet manifold and, according to Audi, provides excellent charge cooling despite the challenging requirements of the engine’s Miller combustion cycle. Notably, compared with previous air-air charge cooling solutions, it enables more consistent control of charge temperature, which is vital for combustion stability at high boost levels. Furthermore, the location close to the inlet helps improve throttle response. However, due to the location of the throttle valve between the turbo’s compressor and the inlet to the charge cooler, it was necessary to add watercooling to prevent overheating of the flap and potential leakage due to expansion.

STARTUP SOPHISTICATION

As noted, the EA888evo5 features an electronic cam adjuster on the inlet, which gives 156° of adjustment, compared with the 60° available on the old hydraulic system. According to Audi (which led development), using the full range of adjustment to reduce compression meant that vibrations on startup could be reduced by one-third, despite the higher CR of the new engine. Impressively, this improvement in NVH was achieved even with a simplification of the Audi valvelift system (AVS) on the PC2 variants.

Previously, this used four separate cam pieces with eight adjusters; a complex system that added to package space requirements and cost. The new system brought together the two pairs of cam pieces, with the switching action achieved using two double actuators. This approach opened up space around the cylinder head, which enabled tighter packaging of the charge cooler while also simplifying production. By using a precision sleeve to join what were previously separate cam pieces, the existing production line could be retained. For the PC1 variant, Audi was able to eliminate the AVS entirely.

VARIABLE ADVANTAGES

Key to realizing the increased potential of a more extreme Miller cycle was the development of an all-new turbocharger for the EA888. Whereas previous iterations had used a traditional setup with a wastegate, the evo5 deploys a VGT unit. To achieve the higher boost levels needed to facilitate the Miller cycle required a turbo with a greater pressure ratio. Although this could be done with a traditional wastegate, with potentially greater peak efficiency, high exhaust gas temperatures (EGTs) would become an issue. With a VGT, due to the lack of wastegate mass flow and better cylinder scavenging, EGTs are lower (1,020°C in the case of the evo5). The only real downside to the use of a VGT was a slight reduction in response, but this could be mitigated by other parameters to the point where it is indiscernible to drivers. Extensive simulation, both 1D and 3D, was conducted to match the turbo behavior to the desired combustion characteristics, reducing the time spent on development loops and cutting back on physical prototyping.

COMBUSTION REFINEMENT

Like its predecessor, the EA888evo5 harnesses the Miller cycle but in a more extreme form to facilitate λ=1 running at all loads and higher compression. To achieve this required that the turbocharging, charge cooling, valve timing and combustion chamber design all work in harmony. A key factor is maximum possible compression of the incoming charge air outside of the combustion chamber, coupled with excellent heat extraction by the charge cooler. This helps overcome the disadvantages of the Miller cycle’s early closing valve timing while avoiding issues with knock without needing to retard ignition timing and thus reduce output.

Like its predecessor, the EA888evo5 harnesses the Miller cycle but in a more extreme form to facilitate λ=1 running at all loads and higher compression. To achieve this required that the turbocharging, charge cooling, valve timing and combustion chamber design all work in harmony. A key factor is maximum possible compression of the incoming charge air outside of the combustion chamber, coupled with excellent heat extraction by the charge cooler. This helps overcome the disadvantages of the Miller cycle’s early closing valve timing while avoiding issues with knock without needing to retard ignition timing and thus reduce output.

Achieving this was far from straightforward; for example, Audi highlights the challenge of achieving high charge motion despite the early closing intake valves, while also optimizing the combustion chamber shape in the limited space available at TDC given the high CR. The result was that notably higher boost pressures (up to 600mbar) could be tolerated than with the evo4 engine, with subsequent increases in torque (20Nm for the PC2) and efficiency gains in the region of 2-3% in many areas of the operating map.

CLEAN RUNNING

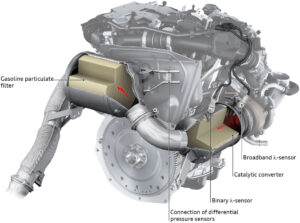

Both the EA888 and EA839 revisions feature new exhaust gas aftertreatment systems, optimized to meet future emissions regulations and provide a more compact overall powertrain package. For the EA888evo5, Audi has developed what it calls a ‘global, cost-optimized emissions toolkit’, for integration into transverse and longitudinal platforms. By positioning the catalytic converter and gasoline particulate filters close to the engine, light-off times for the catalyst are improved and active regen avoided. Where necessary, a secondary catalytic converter can be used (for example, to meet US SULEV requirements). In longitudinal fitments, the catalytic converter is mounted at the turbine outlet, with the particulate filter fitted transversely across the back of the engine. For transverse mounting, a combined catalytic converter and particulate filter allows the entire aftertreatment system to fit behind the engine.

Both the EA888 and EA839 revisions feature new exhaust gas aftertreatment systems, optimized to meet future emissions regulations and provide a more compact overall powertrain package. For the EA888evo5, Audi has developed what it calls a ‘global, cost-optimized emissions toolkit’, for integration into transverse and longitudinal platforms. By positioning the catalytic converter and gasoline particulate filters close to the engine, light-off times for the catalyst are improved and active regen avoided. Where necessary, a secondary catalytic converter can be used (for example, to meet US SULEV requirements). In longitudinal fitments, the catalytic converter is mounted at the turbine outlet, with the particulate filter fitted transversely across the back of the engine. For transverse mounting, a combined catalytic converter and particulate filter allows the entire aftertreatment system to fit behind the engine.

The EA888 will undoubtedly remain the mainstay of the VW Group’s larger ICE platforms (including models still built on the MQB transverse platform). The evo5 iteration is an impressive step up, hitting 38% thermal efficiency while sporting many features to improve its production efficiency as a ‘global’ engine for the group’s various brands.