Volkswagen subsidiary PowerCo SE says it is planning to introduce a completely new manufacturing process in its battery cell production plants in Europe and North America. The company claims that the electrode coating technology will significantly boost efficiency and sustainability in volume battery cell production. Based in Salzgitter in Germany, the battery firm aims to industrialize the so-called dry coating process, which it states allows a decrease in energy consumption of about 30% (compared with current, wet coating processes). Internal tests have already proved successful and, together with German printing machine specialist Koenig & Bauer, PowerCo will seek to further develop and industrialize the procedure.

Thomas Schmall, group board member for technology at Volkswagen and chairman of the supervisory board of PowerCo, commented, “Technologies like dry coating showcase PowerCo’s technological prowess. We have the necessary know-how and the right experts to take cell production to a new level and offer significant cost advantages to our customers. Our objective is to establish an industrial production of sustainable and affordable batteries.”

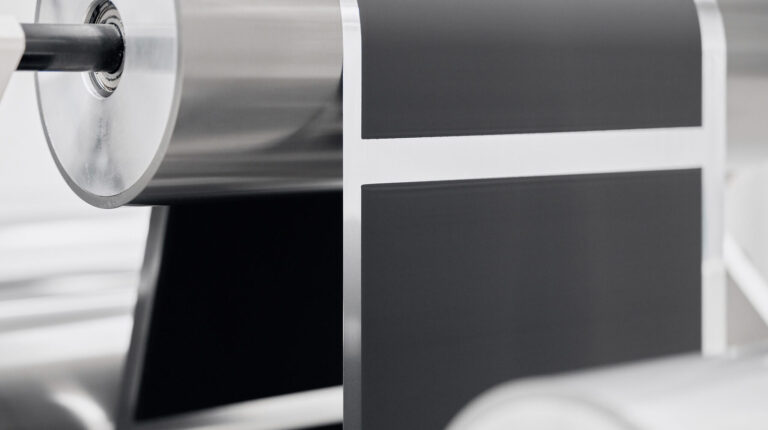

To achieve this goal, PowerCo and Koenig & Bauer have signed a joint development agreement. Together they will develop a roller press for powder coating electrodes on a large industrial scale. The process enables the manufacture of electrodes without wet coating and the subsequent need to dry them at high costs. With the new procedure, the most energy-intensive part of cell manufacturing and the use of chemical solvents are no longer required. PowerCo is already testing and optimizing the technology in a pilot line in one of its laboratories in northern Germany. As a printing specialist, Koenig & Bauer will develop a machine for industrial powder coating.

According to PowerCo estimates, the new technology has the potential to save about 30% of energy and 15% of floor space required and will therefore save hundreds of millions of euros each year. Frank Blome, CEO of PowerCo SE, remarked, “What the solid-state cell is to the product, dry coating is to production – a real game-changer. If scaled successfully, it will give us a unique position on the market and definite competitive advantages.”

In current industrial battery electrode production, the battery materials are mixed to a slurry with additives and liquid solvents. Afterward, they are coated onto foils of copper or aluminum, then dried and calendered.

PowerCo’s process allows the calendering of the powdery basic materials directly onto the foil, similar to a printing procedure. As a result, two of the four process steps in electrode manufacturing become obsolete. The powder coating can be applied onto the foil in an extremely fine and even manner; the resulting layer is about as thin as a hair. This guarantees excellent spatial energy density and a long lifespan, while improving the fast-charging ability of the battery.

The new technology reduces floor space required by 15% – an enormous saving potential. Per building block of a regular gigafactory with a production capacity of 20GWh, four parallel coating and drying lines can be saved, equaling an area of 7,000m2. As a result, the exterior length of the plant can be reduced by about 100m. Not having to operate the energy-intensive drying furnaces and suction systems is predicted to save the energy equivalent of the annual consumption of 40,000 private households. Furthermore, it is no longer necessary to use chemical solvents that have to be laboriously recycled at high energy costs in silo-like towers outside the plants.