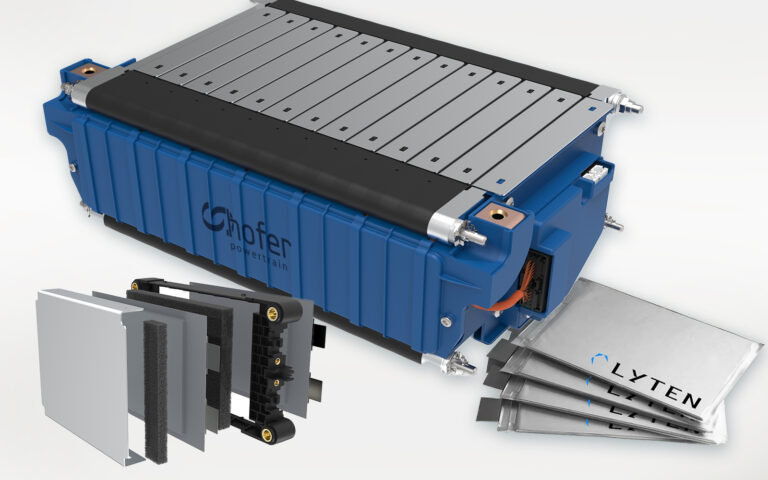

Hofer Powertrain has developed a battery module using next-generation lithium-sulfur cells from project partner Lyten that, according to Hofer’s projections, will enable energy densities twice that of lithium-ion, and therefore a wider range of low and high temperature performance. The joint project is focused on delivering these cells’ performance within a module structure, particularly their electrical load capacity and cycling stability.

The companies say that the lithium-sulfur (Li-S) technology offers a more sustainable, lighter and higher-energy-density battery storage solution by eliminating the use of critical materials such as nickel, cobalt, manganese and graphite. Hofer Powertrain is currently building a battery module to further progress the potential of this new cell chemistry at the module and pack level.

From a supply chain perspective, the module eliminates the use of nickel, cobalt, manganese and graphite, and therefore enables local sourcing of its minerals in the USA and EU. Combined with Lyten’s potential for a simplified cell manufacturing process, the project is expected to achieve CO₂ savings of over 60% at industrial scale.

Lyten will provide the Li-S-based battery cells and Hofer Powertrain will be responsible for complete system development and integration, from module architecture to functional validation. Hofer Powertrain’s battery engineering team has transferred the cell chemistry into a modular battery concept specifically designed for pouch cells. The system is said to feature a streamlined design that allows for easy cell replacement and addresses all critical aspects of development: mechanical, thermal and electrical.

The battery module features a modular architecture designed for applications up to and beyond 800V and incorporates Hofer Powertrain’s cell monitoring unit (CMU), which integrates into the architecture and enables precise monitoring at the module level.

Johann Paul Hofer, CEO of Hofer Powertrain, said, “Our customers demand technologically robust, futureproof solutions. For decades, we have been delivering unique battery concepts by combining proven technologies with innovative architectures and at the same time, have the capability to quickly implement and validate new cell chemistries like lithium-sulfur at the system level, in a reliable and application-oriented manner.

“With our extensive development and testing capabilities, the current expansion of our battery and testing centers, and our long-standing expertise in electric powertrains, we create the foundation for bringing innovations to market readiness at an early stage.”

Dan Cook, CEO and co-founder of Lyten, added, “Demand for lithium-sulfur batteries is skyrocketing as customers seek lighter weight, lower cost batteries built with abundantly available local materials. We are incredibly excited to work together with Hofer Powertrain and its years of pack and module experience to accelerate adoption of lithium-sulfur. EVs, micromobility, drones, satellites, BESS and many more applications are all going to benefit from this joint project.”

In related news, Hyundai Motor Company recently unveiled the upgraded Xcient fuel cell class-8 heavy-duty truck, which features advanced hydrogen technologies tailored for the North American market. Click here to read the full story.